The bulk of construction tasks requires the help of heavy equipment vehicles and other machines to accomplish them. This makes choosing the right vehicle all the more challenging because you must use a construction vehicle that can achieve your goal. You, therefore, must find the best vehicle for the job to accomplish your projects on time and with ultra-efficiency while maintaining a safe environment.

Here are the key things to consider when choosing the right vehicle for your construction business.

Table of Content

The Scope and Size Of The Job

The topmost factor you’d want to consider when selecting a construction vehicle is the scope of the project as well as the magnitude of the job. These two will determine not only the type of vehicle you will need but also the size of the vehicle you’d need.

For instance, if you have a large-scale job building a skyscraper, you will most certainly need a large vehicle like a Komatsu PC490LC-11 to help dig up a strong and solid foundation.

Conversely, if you have a two-storey hotel renovation project, you may need just a small excavator like a John Deere 35G for demolitions

It would be best if you looked at the sizes of projects on all fronts before making a decision. That means looking at the project’s size both vertically and horizontally. Because while you may need a crane for a tall building, you certainly don’t need one if building a large mansion.

Depending on the nature of your business, you can choose to buy, lease, or rent a construction vehicle. All are viable ways to acquire a construction vehicle though each has its own set of pros and cons.

If you are buying or leasing, you must first determine what scope and size the bulk of your projects will be over the lifetime of your business. If focusing on residential construction, there is hardly a chance you’d need large construction vehicles.

Fortunately, with renting construction equipment, you can always order a particular vehicle depending on your client’s scope of work. There isn’t as much pressure to determine beforehand the size of vehicle you will need as there is with buying or leasing.

If finances allow you, always go for larger vehicles. Even though they are costly both to purchase and maintain, they are much more efficient and hold up better even under difficult working conditions. In addition, their ROI is higher than with smaller construction vehicles.

The only downside is that if the job is smaller, then the combined costs of renting, fueling, and operating a vehicle will most likely exceed what you’re being paid to do the job in the first place. It is even costlier than when using a smaller vehicle to work on bigger loads. Hence you need to carefully weigh the pros and cons of using both small and large construction vehicles before making a purchase commitment.

Quality

Look for high-quality construction vehicles from reputable brands like John Deere, Komatsu, Caterpillar, Ditch Witch, or even a Bobcat. Do not compromise on the quality at whatever cost. Construction vehicles are subjected to tedious tasks and harsh, unfamiliar, or unpredictable weather conditions like snow, heavy rains, and extreme temperatures, which can damage, weaken or even break parts. If you go for a cheaper brand, there is a high likelihood that the quality is sub-par, and you will frequently be dealing with functionality and technical issues.

If you’ve had to halt a construction project at its climax just to fix a broken-down crawler carrier or excavator, then you know the frustration and consequences that follow after that. You will not only lose time and money, but you may also lose clients if it becomes a regular concern.

Heavy equipment vehicles can be very expensive to purchase (although you can save some money to buy a used construction vehicle) but they are an excellent investment in the long run with a good ROI. You will save so much on repair and maintenance costs when the vehicle is strong and made of superior materials.

Also, substandard construction vehicles are hazardous to both the operators and everyone else working on a site.

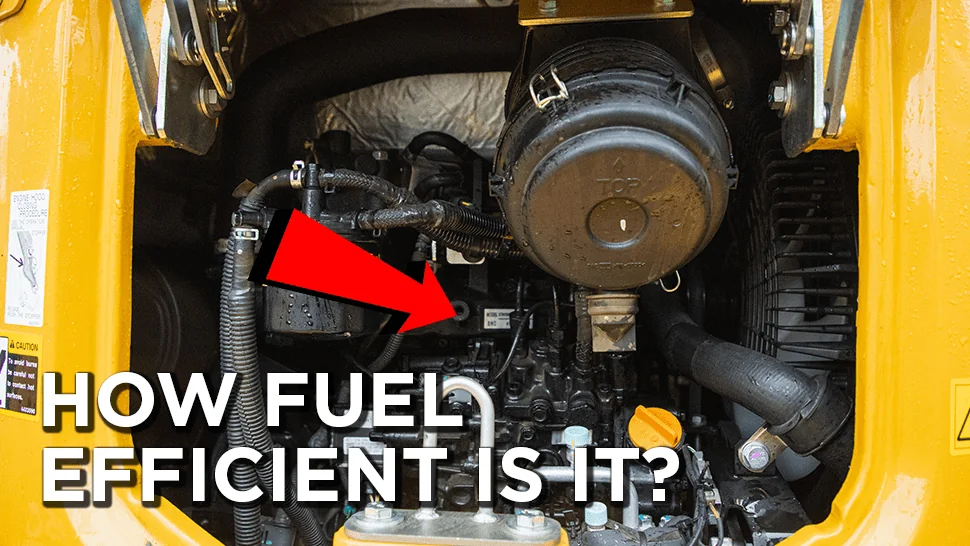

Fuel Efficiency

The other key thing that you want to examine is how fuel-efficient the construction vehicle is, and you can only tell how fuel-efficient it is by checking how much fuel it consumes while at work. A vehicle that consumes less fuel while still giving optimum results is what you want to pick. This means you will spend less time and money at the filling station and more time at the construction site.

Given how expensive heavy-duty construction equipment is, you honestly do not want to shell out more on fueling costs down the line.

Embedded Technology

Finally, you want to check what technology the vehicles feature. A vehicle embedded with technology will greatly assist you in getting work done faster, efficiently, and to some greater degree safely as compared to non-tech vehicles.

For instance, a dump truck with a rearview camera will help you offload much faster than one without. You won’t have to spend so much time trying to find the right position to offload.

Other useful features you want to be looking out for are GPS, telematics, onboard digital site plans, payload weighing, navigation, and steering assistance. You also want a vehicle that can be operated remotely with construction management software.

Availability of Parts and Specialists

Your vehicle will be an integral part of your construction business, so you, therefore, want to make sure that you can have it fied as soon as it breaks down. This means having quick and easy access to spare parts and the specialists to fix them.

Choose a widely available brand with spare parts and ensure that you can easily reach a specialist to consult if the need arises. With readily available spare parts, you could even DIY some repairs and maintenance. For instance, you can easily change the hydraulic filters on a John Deere 650K or even replace the engine oil. Just be sure to wear the right heavy equipment safety gear.

![]()

Learn how to repair and maintain your construction vehicle by visiting FortisHD maintenance.