Buying pre-owned heavy equipment could be a cost-effective choice as long as you know the actual condition of the machine.

But where and what should you inspect? Overall, one should look for the following:

- Bucket wear.

- Pin ware.

- Condition of shims.

- Overview of hoses.

- Obvious wear on the tracks and undercarriage.

- Condition of engine oils and hydraulics.

Join one of the technicians from Tekamo HD as he guides us and shares his experience in the basic steps and red flags of a pre-sale inspection on a used John Deere 250G LC Excavator.

Want to see the video version?

Table of Content

Inspection Overview

We’ll start with the obvious. Any signs of wear and tear around the machine. Look for dents, cracks on trackpads or welds, leakages, and loose bolts.

Although the inspection should be thorough, you must double-check certain things depending on the equipment’s job. For example, look for dents or damages at the ROPS (Rollover Protective Structure), FOPS (Falling Object Protective Structure), and the protection screen if it’s a forestry machine.

Check the hydraulic oil fillers and vents for sweating or gone top seals, which is a consequence of topping up the oil too much.

Let’s start with an outer inspection, and from there, we’ll check the machine’s operation and finish by taking some fluid samples.

Batteries

Check if there is a night switch. Kill switches protect batteries from excessive drain.

Look for corrosion and tightness in the connections.

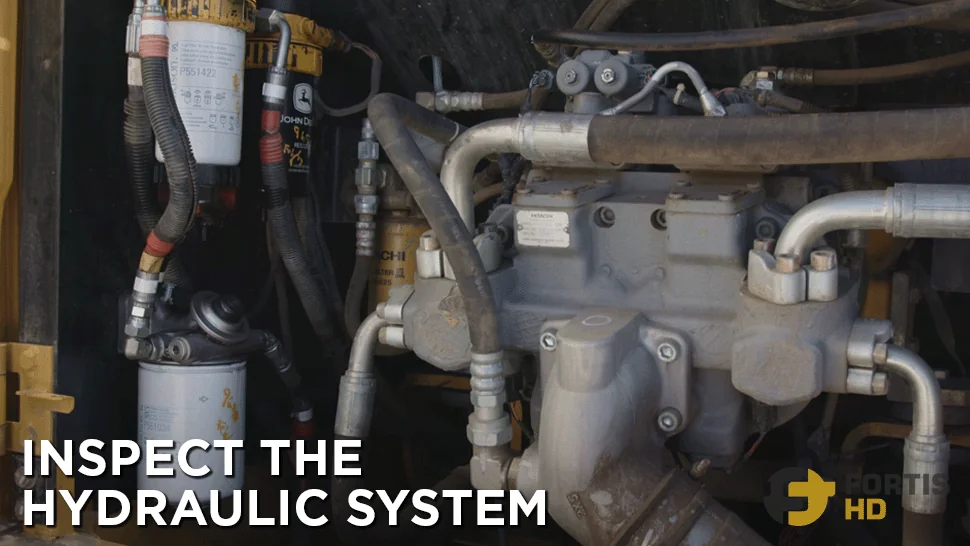

Hydraulic Pump

Is the pump clean? Are there sweats?

Pay attention to suction lines, as they are usually sweaty ones.

A clean machine, especially in its inner components, might indicate that the owner has taken good care of it.

Take out the dipstick to check the condition of the pump drive.

Whenever you check the oil level with a dipstick (engine, hydraulic, etc.), it should be between the top and bottom marks or slightly above the top mark.

Bolts and Seals

Look for the bolts in the trackpads. They come loose fairly often.

Also, pay attention to leaks in the cylinder seals.

Engine and Swing Motor

Start checking the coolant level in the expansion tank.

You’ll need a flashlight for what’s next.

Search for obvious leaks from hoses and cracks on belts.

We found minor cracks on the serpentine belt. But it was nothing to worry about in the short term. As long as the belt is not about to rip, it can wait a bit longer.

Now, pull the dipstick. We’ll share some tips with you throughout the article. Here comes the first one.

The engine oil has coolant or water if you see milkiness on the dipstick. None belong there, so keep an eye on that.

Second tip: How do you know if it’s been long since the last oil change? Rub some oil in your hand. If the stain doesn’t go off, the oil is really old. By the way, the stain can stay there for a week.

Suppose the oil level is low. Ask yourself and the owner:

Why is it low?

Is it burning oil through the pistons or crankcase?

Although you can’t know for sure with a visual inspection, it can give you an edge in the negotiation.

Finally, for diesel engine machines, check if there’s a positive air shut-off and if it’s not tripped. A positive air shut-off blocks the intake air from reaching the combustion chamber, protecting people and equipment from diesel engine runaway.

Diesel runaway is a rare and severe condition in diesel engines. It happens when the engine draws extra fuel from an unintended source and speeds, producing up to ten times the engine’s rated output. The engine overheats and seizes or can even explode.

After checking the engine, pull the swing motor’s dipstick.

Apart from ensuring the oil level is between the top and bottom marks, we recommend checking the dipstick twice. The first read might not be accurate.

Attachment

Finish the overall inspection by checking whatever attachment the machine has. In this case, a bucket.

If you can flip up the bucket, look for cracks or dents on both sides.

Also, check if the thumb alignment and positioning need tweaking.

If the excavator you’re inspecting has a mechanical quick coupler system (as in this case), check the condition of the bucket keeper (wedge bar).

All the mentioned checks help us discard machine abuse.

Machine Operation Test

Start up the machine and let it warm for a minute.

We’ll check the condition of the hydraulic pumps and the undercarriage components with a track test.

Hydraulics

Check the hydraulic oil level in the sight glass. To get a proper reading, put the machine in the service position, that is:

- The stick cylinder is fully closed.

- The bucket cylinder is fully closed.

- The thumb cylinder is fully closed.

- The boom is extended (its cylinder won’t be fully closed).

Test the hydraulics of the boom, stick, bucket, and thumb. Is the operation smooth? Do you hear friction noises? See any leaking?

Check also the excavator swing brake for noises or leakages.

Finally, to check the condition of the hydraulic pumps, put the bucket on the ground and push down with the boom. The hydraulic pumps are in good condition if the boom lifts the cabin.

When the pumps struggle, you’ll need to use the boom and the stick to lift the cabin.

Tracks

Do a short runway forward and backward.

Check if the machine goes in a straight line or pulls left or right.

Also, pay attention to any excessive undercarriage noise. Is any roller seized up or all move?

Next, use the boom to lift both sides of the undercarriage and roll around the tracks.

Check for squealing or excessive noises. How is the track tension? Is it slack or tight?

Inspect if the sprocket teeth are sharp, which means excessive wear. Also, check the sprocket’s bolts. They tend to come loose over time.

Attachment

Now that the hydraulics are within the operative temperature check the bucket pins’ condition.

Shake the bucket sideways to see if it moves and wobbles. There will always be some play. What you need to pay attention to is excessive pin movement.

Slowly push down on the bucket and again look for excessive play. In this case, for a 9,700-hour machine, the play on the bucket, boom, etc., is what you would expect. It was a fair amount, but still something to be aware of.

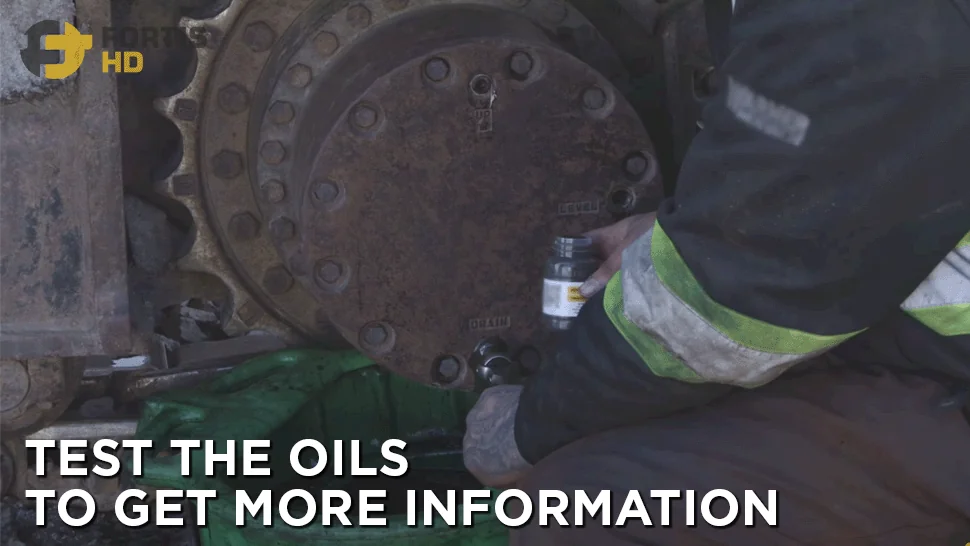

Fluid Samples

The more samples you can get, the better. They’ll complement your visual inspection, giving you a complete understanding of the machine.

Bring enough oil sample containers and brake cleaner to loosen bolts.

Final Drive Oil

First, position the final drive so the up plug is at the top (12 o’clock) and remove the level plug. You’ll hear a pop sound (depressurization).

How do you know if the final drive oil level is correct?

When you remove the level plug, no oil should come out. The oil level must be just below the level plug hole. If a bit of oil comes out when removing the plug, that’s ok as long as it’s not excessive.

In this case, the level plug hole spilled excessively, and the color was fairly shiny. Why is that? Here comes our third tip.

Overfilling oil in the final drive is generally a consequence of hydraulic motor seal leaking, while shining means the presence of metal.

Engine and Swing Motor Oil

Taking the engine oil sample is pretty straightforward. You need to remove the belly plate to access the drain.

Just be aware of the machine’s temperature. The oil might burn you.

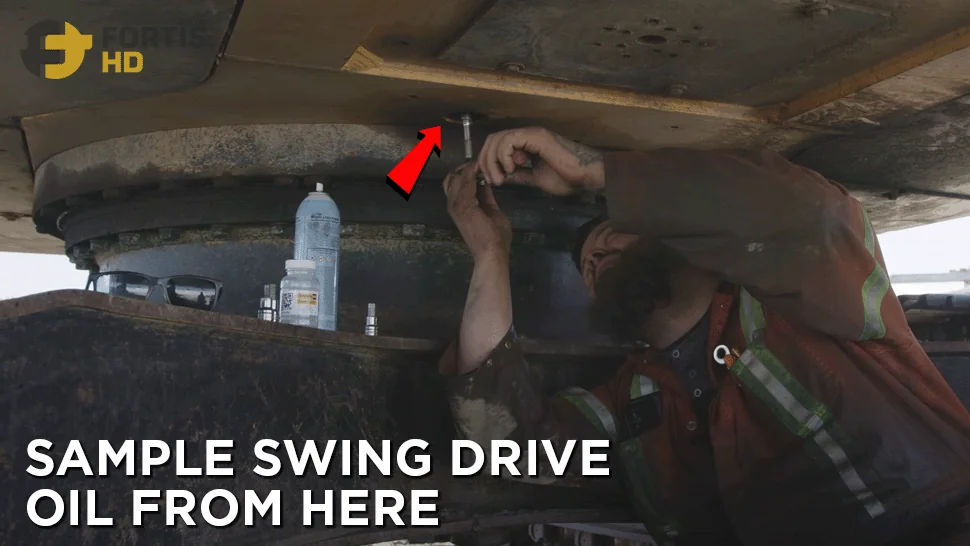

While underneath the machine, take an oil sample from the swing motor.

The oil sample containers have a fill line. Try not to go over it.

Coolant and Hydraulic Oil

To collect the coolant sample, just pull off one of the lines of the radiator.

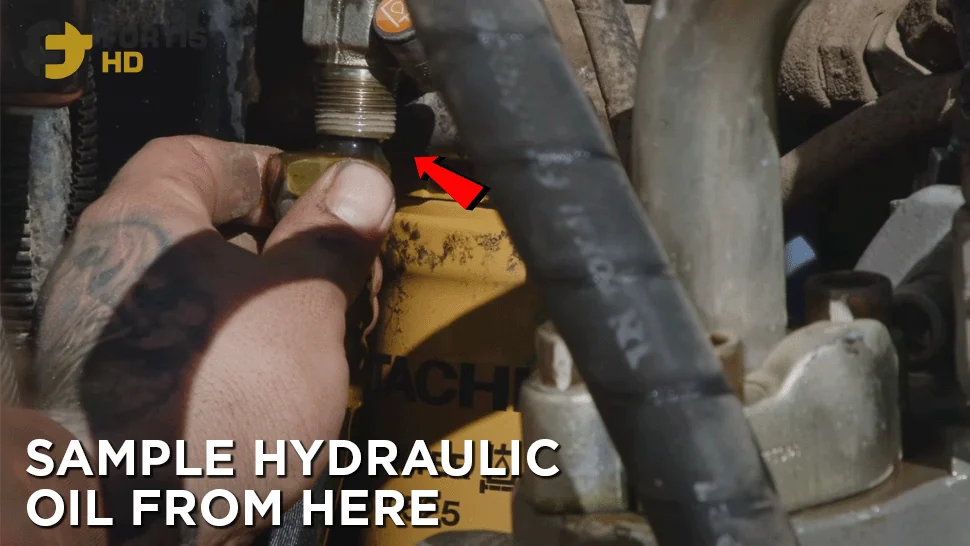

Finally, get the hydraulic oil sample by pulling off one of the lines in the back from the hydraulic high-pressure filter.

Additional Info You Need to Ask For

Besides everything we covered in this article, ask the owner the following about the machine:

- Where did it work?

- What did it do?

- Did it run an attachment besides the bucket? A hydraulic breaker? A grappler?

All those questions will guide you to focus your inspection more on certain parts than others.

You can do a heavy equipment pre-sale inspection yourself. However, at Tekamo HD, we have expert technicians who will thoroughly inspect the equipment you want with samples and everything, so you’ll know exactly what you are getting into.

If you plan on buying a pre-owned skid steer, mini-excavator, or compact track loader, turn it like a new machine by purchasing the best replacement tires and high-quality aftermarket tracks from Fortis HD.