Adjusting track tension on mini excavators is something you can do yourself within minutes. It’s a simple task that will extend the lifespan of your rubber tracks and other undercarriage components.

If your tracks are beyond their useful life, learn how to replace them with our article How to Put a Track Back on a Mini Excavator.

Before breaking down the steps to adjust the track tension, we need to know how frequently to do it and to identify whether the tracks are loose or too tight.

Visit the Fortis HD tracks section to see our exceptional lineup of OEM-certified rubber tracks for mini excavators, masterfully engineered for peak performance and efficiency.

Rubber Track Maintenance

Maintenance intervals vary among manufacturers. Most recommend checking the tension daily or as required. Others go for intervals of 50 or even 250 hours. See your operator’s manual for OEM tracks or the manufacturer specifications for aftermarket tracks.

Our Ultimate Maintenance Guide (based on the most popular brands) shares recommended hour intervals to check and adjust the track tension on mini excavators, skid steers, and compact track loaders.

Signs That Your Tracks Are Loose

A clear indicator of loose rubber tracks is excessive sag between the sprocket and the front idler. Check the sageness on a level surface.

When tracks frequently slip off the rollers or the sprocket, especially when turning or navigating uneven terrain, it indicates inadequate tension.

When the tracks are too loose, your machine will be shaky, especially when traveling at higher speeds or on slopes.

Loose tracks can produce rattling or banging noises during operation.

If you notice reduced productivity or difficulty in maintaining straight-line travel, it could be due to loose tracks causing uneven movement.

Signs That Your Tracks Are Tight

If your tracks wear prematurely, you are probably adding too much tension. Look for cracks, tears, or deformations, particularly on the outer edges of the tracks.

Two clear signs of tight tracks are a rougher ride experience (Increased vibrations), especially when driving over rough terrain, and a lack of sageness (tracks appear stretched and overly taut).

Operational signs of overly tight tracks are:

- Reduced traction, particularly in soft or muddy terrain.

- Higher fuel consumption. Tight tracks increase moving resistance.

How to Properly Adjust Track Tension

Park the machine on horizontal ground.

Push the blade down first to lift the back end of the machine.

Then, push the boom and bucket down on the ground to lift the excavator completely.

If your machine has no blade, turn the cabin 90 degrees toward one of the tracks. Keep an angle of 90 – 100 degrees between the boom and the arm. Push down with the bucket and boom.

Lift the Pilot Shutoff Lever to the locked position to prevent accidental hydraulic movements.

Optionally, put some blocks under the machine frame for extra security.

The average sag measurement manufacturers recommend is 10 – 15 mm (0.4 – 0.6 in) between the bottom roller closest to the center and the rubber track. However, you must consider the roller type and whether the track has a joint.

For tracks with a joint, look for a visible seam or a mark (M or “oo”). Drive the track until the mark is on the top center between the idler and the sprocket.

For jointless tracks, check the tension in any position.

Now, check the type of bottom roller in your undercarriage. Remember, the one closest to the center.

Table of Content

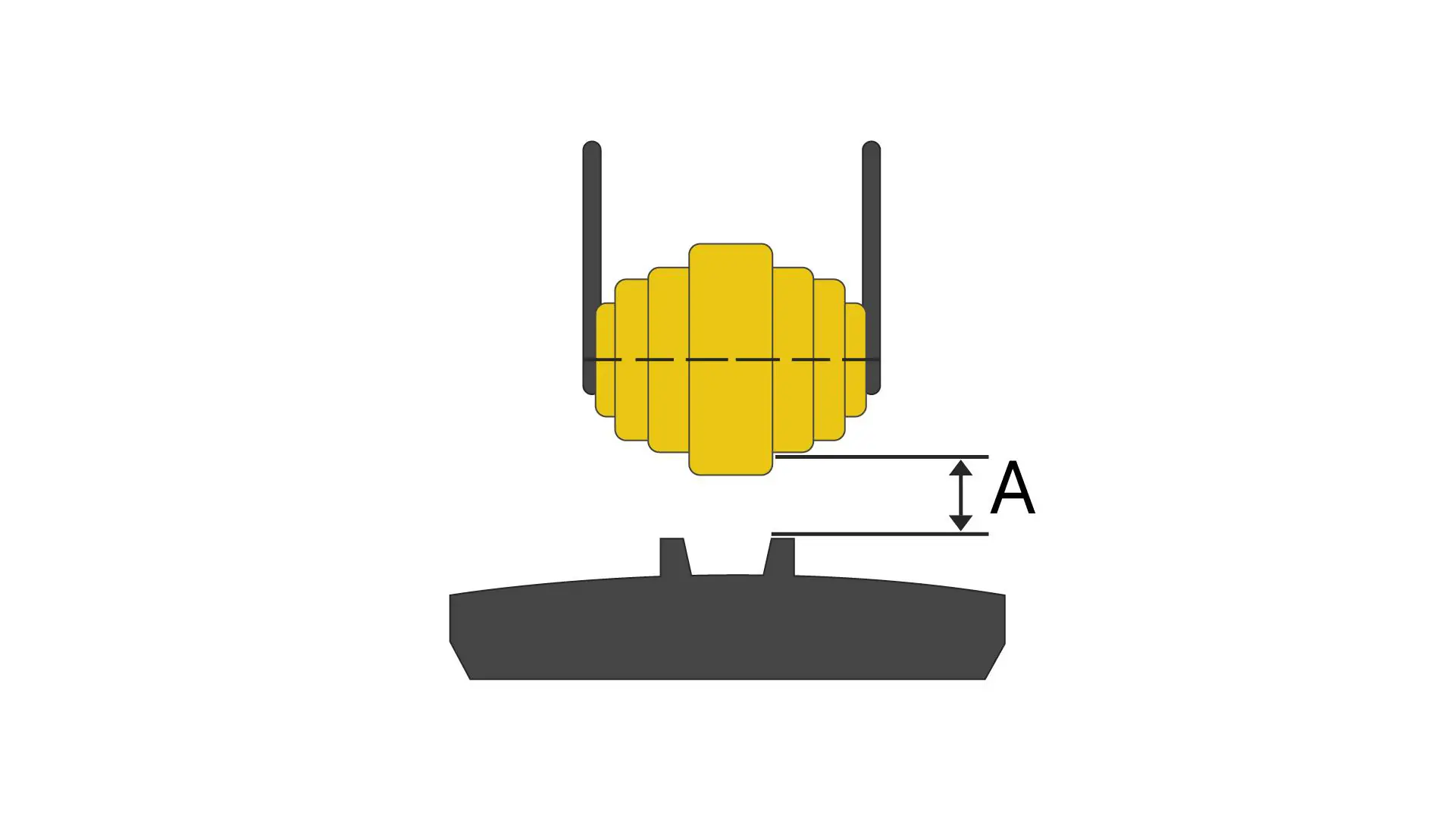

For Single Flanged Inner Bottom Rollers

Measure the track sag distance from the bottom of the roller to the inner ridge of the rubber track (A distance in the image below)

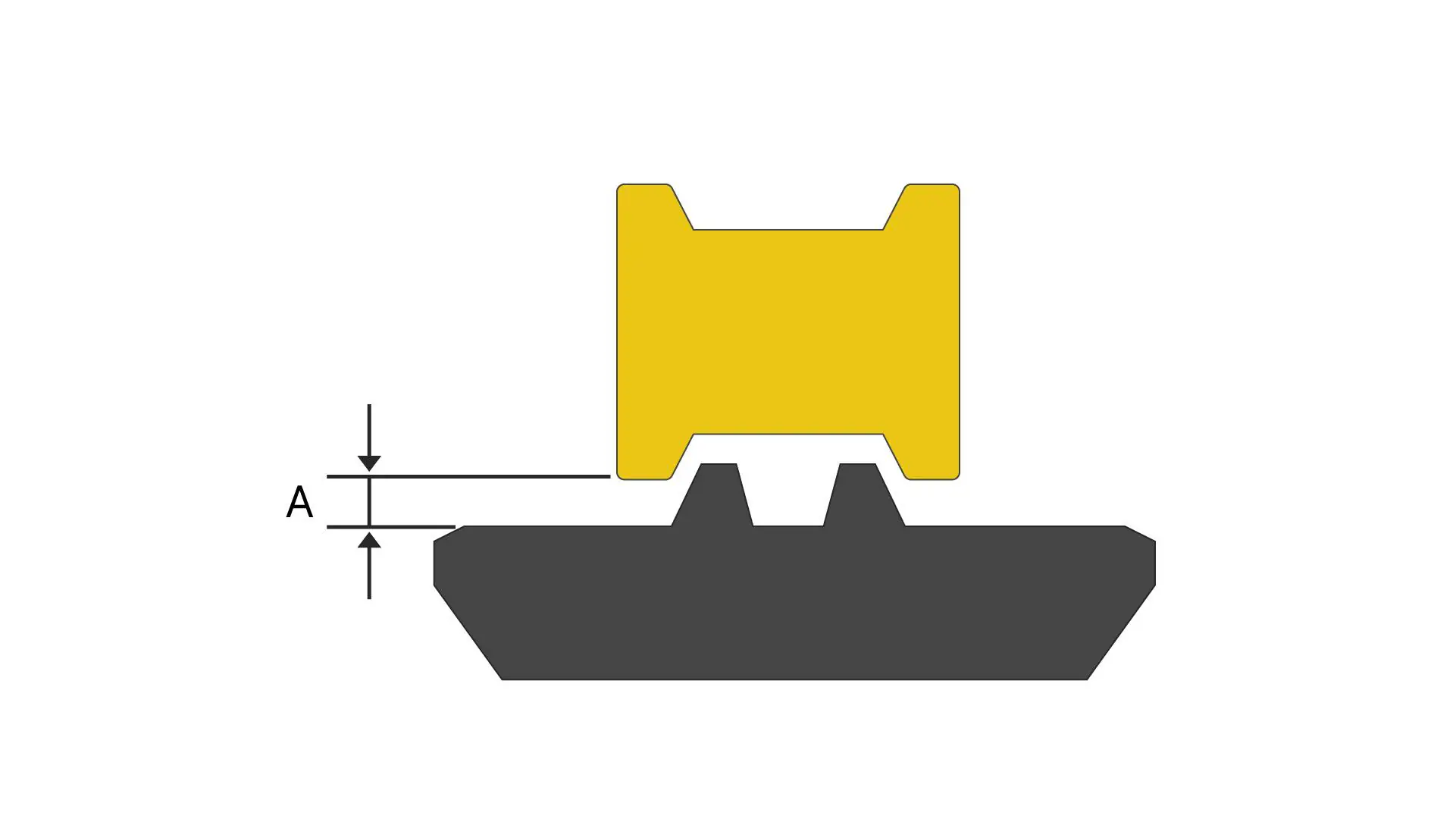

For Single Flanged Outer Bottom Rollers

Measure the track sag distance from the flange of the bottom roller to the rubber track surface (A distance in the image below)

Look for the grease valve access hole in the track frame and remove its cover.

To loosen your tracks, turn the grease valve counterclockwise with a wrench or deep socket until you see grease coming out from the grease outlet.

To tighten the tracks, pump grease through the grease nipple with any grease gun (we prefer an electric gun).

Finish by rotating the tracks forward and backward for 30 seconds and recheck the sag clearance.

The process of adjusting the tension on steel tracks is similar. In the following video, Keith shows how to adjust the tracks of a Cat 314E Excavator within minutes.