If you’re doing this service yourself, visit FortisHD to purchase a service kit with every filter you need, or visit Tekamo HD to hire an expert service technician.

In the fifth post of this series, we serviced the radiator of the 17G Excavator. Check out our previous post about cleaning the radiator to catch up.

In this final post, you’ll learn how to change the final drive oil to complete the 500-hour service interval on the 17G Excavator.

Do you prefer to see a video tutorial instead?

Need to save time? The following table shows every filter you need for the complete 500-hour service interval:

| Item | OEM | Part Number | |||

|---|---|---|---|---|---|

| Aftermarket equivalent | |||||

| Baldwin | Donaldson | Wix | Blumaq | ||

| Engine Oil Filter | M806418 | B1400 | P502067 | 51365 / 51365XP | N/A |

| Hydraulic Tank Oil Filter | 4692230 | N/A | N/A | N/A | N/A |

| Hydraulic Filter O-ring | T110443 | N/A | N/A | N/A | N/A |

| Hydraulic Pilot Filter with O-ring | 4294130 | PT9424 | P502508 | R12E10CV | N/A |

| Primary Fuel Filter | MIA883874 | N/A | N/A | N/A | N/A |

| Secondary Fuel Filter | MIU803907 | N/A | N/A | N/A | N/A |

| 2 x Fuel Filters O-ring | M800893 | N/A | N/A | N/A | N/A |

| Engine Rocker Arm Cover Gasket | MIU800300 | N/A | N/A | N/A | N/A |

| Engine Air Filter | M113621 | RS3715 | P822686 | 46449/46449FR | N/A |

| Air Cleaner Dust Unloader Valve | 4383877 | N/A | N/A | N/A | N/A |

| Engine Oil | TY26674 | N/A | N/A | N/A | N/A |

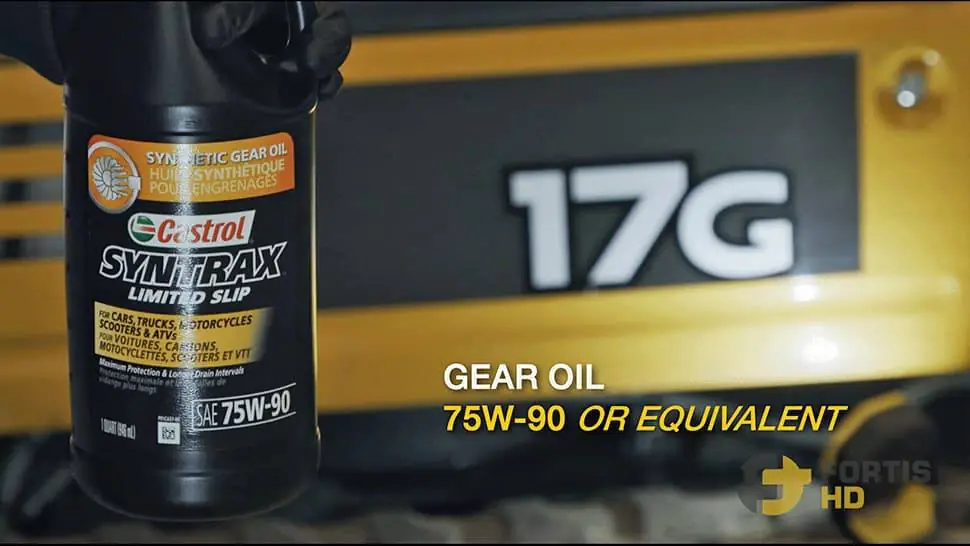

| Gear Oil | TY6296 | N/A | N/A | N/A | N/A |

| Hydraulic Oil | 2908-050 | N/A | N/A | N/A | N/A |

Table of Content

Drain the Final Drive Oil

Track the machine (forward or backward) to set up correctly one of the final drives — the drain plug must be on the bottom.

To set up the other final drive, start the machine, swing it over, and slightly lift the track in the air. Jump out of the machine, put the safety lever down, and move the track until the final drive is in the correct position.

Put the safety lever back up and lower the track.

The plugs have O-rings that tend to go in, making it difficult to loosen them. There are several ways to pull them out.

One way is using a 6mm Allen key with a wrench as a snipe to add more torque. Sometimes, as the machine gets older, the holes of the Allen key plugs start to round and strip, making it even harder to pull out. In that case, hammer an Allen key socket slightly and use a ratchet.

A third way is using a chisel and hammer. Put the chisel on the outside edge of the plug and make a mark straight in. Then put the chisel on the mark at a downward angle and give it a couple of hard hits until you crack it loose. Finish with the Allen key.

There’s one more way to loosen stripped and rounded plugs using a manual impact driver. Attach the Allen key socket to the impact driver, set the impact driver to turn counterclockwise when you hit it, put it in the hole, and give it a hard smack.

Put a drain pan under the final drive.

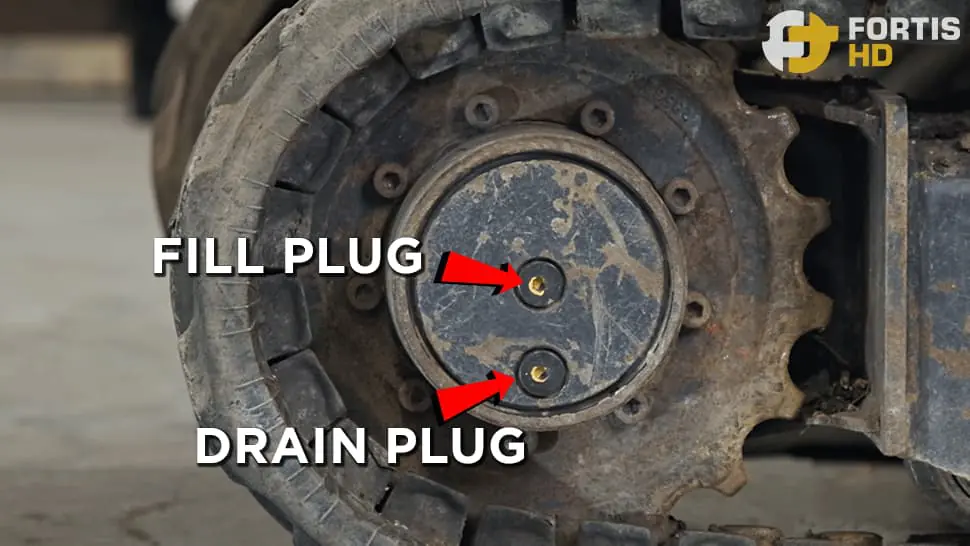

Pull the upper plug out first to check the oil condition and level:

- If no oil comes out, there might be a leak.

- If the oil looks milky, water is getting inside the gearbox.

We recommend sampling your gear oil at the time of service. Refer to the operator’s manual for more information.

Pull the bottom plug out to let the final drive drain entirely. Typically, gear oil gets smelly as it worms out.

Wipe the plug holes using a rag, put the bottom plug back in (there’s no problem if you mix the plugs up), and tighten it using the ratchet with the Allen key socket.

Pour Fresh Final Drive Oil

There are two ways to fill the gear oil.

First, with the final drive in its current position — drain plug on the bottom — pour through the fill plug until oil comes from it.

Second, start the machine and turn the final drive until the drain plug is above 90° (10 o’clock position). Pour oil through the drain plug until it comes out of the fill plug. This method guarantees a more accurate oil level reading.

We will need 1 quart (1 liter) of 75W-90 gear oil.

To avoid leaks while filling the final drive, put a rag around the tip of the gear oil bottle. Ensure to fill until the oil level doesn’t drop down in the fill plug.

Put the fill plug back in and pour a bit more oil so the next time you or anybody else change the oil, know it was at the right level. Finish by putting back the drain plug.

Conclusion

Extending the lifespan of your John Deere 17G Mini Excavator is easy. However, if you don’t have the time or equipment, hire a service mechanic at Tekamo HD.

Be sure to check out the other posts we have in this series:

- Replace The Hydraulic Return Filter And The Pilot Filter.

- Change the Engine Oil and Filter.

- Replace the Engine’s Inner and Outer Air Filters.

- Replace the Fuel and Water Separator Filters.

- Clean The Radiator.

Visit the FortisHD blog for more tips, tutorials, and guides about heavy equipment.

If you’re doing this service yourself, visit FortisHD to purchase a service kit with every filter you need, or visit Tekamo HD to hire an expert service technician.