If you’re doing this service yourself, visit FortisHD to purchase a service kit with every filter you need, or visit Tekamo HD to hire an expert service technician.

In the last post, we changed the fuel and water separator filters

In part 5 of the John Deere 17G 500-hour service interval tasks series, you’ll learn how to clean the radiator.

Do you prefer to see a video tutorial instead?

Need to save time? The following table shows every filter you need for the complete 500-hour service interval:

| Item | OEM | Part Number | |||

|---|---|---|---|---|---|

| Aftermarket equivalent | |||||

| Baldwin | Donaldson | Wix | Blumaq | ||

| Engine Oil Filter | M806418 | B1400 | P502067 | 51365 / 51365XP | N/A |

| Hydraulic Tank Oil Filter | 4692230 | N/A | N/A | N/A | N/A |

| Hydraulic Filter O-ring | T110443 | N/A | N/A | N/A | N/A |

| Hydraulic Pilot Filter with O-ring | 4294130 | PT9424 | P502508 | R12E10CV | N/A |

| Primary Fuel Filter | MIA883874 | N/A | N/A | N/A | N/A |

| Secondary Fuel Filter | MIU803907 | N/A | N/A | N/A | N/A |

| 2 x Fuel Filters O-ring | M800893 | N/A | N/A | N/A | N/A |

| Engine Rocker Arm Cover Gasket | MIU800300 | N/A | N/A | N/A | N/A |

| Engine Air Filter | M113621 | RS3715 | P822686 | 46449/46449FR | N/A |

| Air Cleaner Dust Unloader Valve | 4383877 | N/A | N/A | N/A | N/A |

| Engine Oil | TY26674 | N/A | N/A | N/A | N/A |

| Gear Oil | TY6296 | N/A | N/A | N/A | N/A |

| Hydraulic Oil | 2908-050 | N/A | N/A | N/A | N/A |

Table of Content

Clean the Radiator

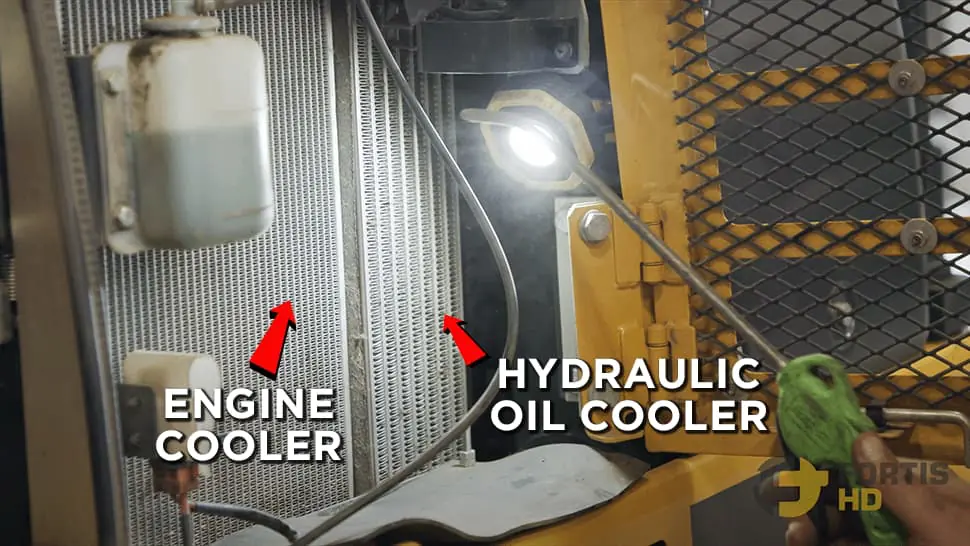

Open up the back and right side compartments to find two radiators. The one to the left is the engine radiator, and to the right is the hydraulic oil cooler. We need to clean both.

You can use special tools for this task, like the rad genie, but a regular blow gun, garden hose, or pressure washer is more than fine for a small machine like the 17G.

If you’re using a pressure washer, take a step back and don’t do it with an angle (stand in front of the radiator). Otherwise, you’ll bend the fins over, restricting the airflow.

Blow all around the fins to remove all the branches, pine needles, and dust to ensure airflow through.

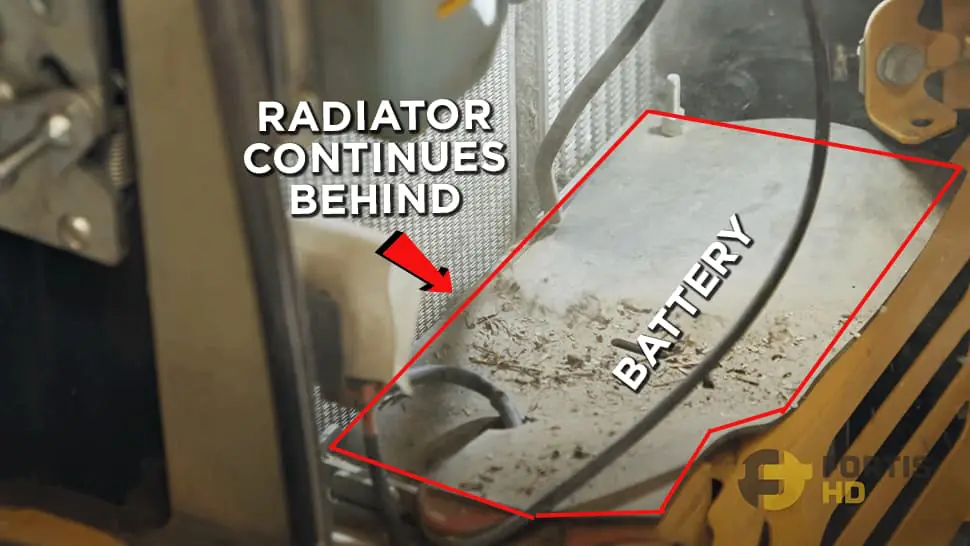

The radiator extends past the top of the battery. Make sure not to miss that spot.

Thoroughly clean the radiators until there is no more dust, branches, or debris.

Check the Coolant Level

When the engine is cold, check the coolant level in the recovery reservoir — it’s connected to the top of the radiator.

If there’s no coolant in the recovery reservoir, the radiator will likely be low on coolant, too.

Next post

In the final post of this series, we’ll change the final drive oil on the John Deere 17G Excavator.

If you’re doing this service yourself, visit FortisHD to purchase a service kit with every filter you need, or visit Tekamo HD to hire an expert service technician.