If you’re doing this service yourself, visit FortisHD to purchase a service kit with every filter you need, or visit Tekamo HD to hire an expert service technician.

In the third post of this series, we completed servicing the engine of the 17G Excavator. Check out our previous post about changing the engine air filters if you want to catch up.

In this post, you’ll learn how to replace the fuel and water separator filters as part of the 500-hour service interval.

Do you prefer to see a video tutorial instead?

Need to save time? The following table shows every filter you need for the complete 500-hour service interval:

| Item | OEM | Part Number | |||

|---|---|---|---|---|---|

| Aftermarket equivalent | |||||

| Baldwin | Donaldson | Wix | Blumaq | ||

| Engine Oil Filter | M806418 | B1400 | P502067 | 51365 / 51365XP | N/A |

| Hydraulic Tank Oil Filter | 4692230 | N/A | N/A | N/A | N/A |

| Hydraulic Filter O-ring | T110443 | N/A | N/A | N/A | N/A |

| Hydraulic Pilot Filter with O-ring | 4294130 | PT9424 | P502508 | R12E10CV | N/A |

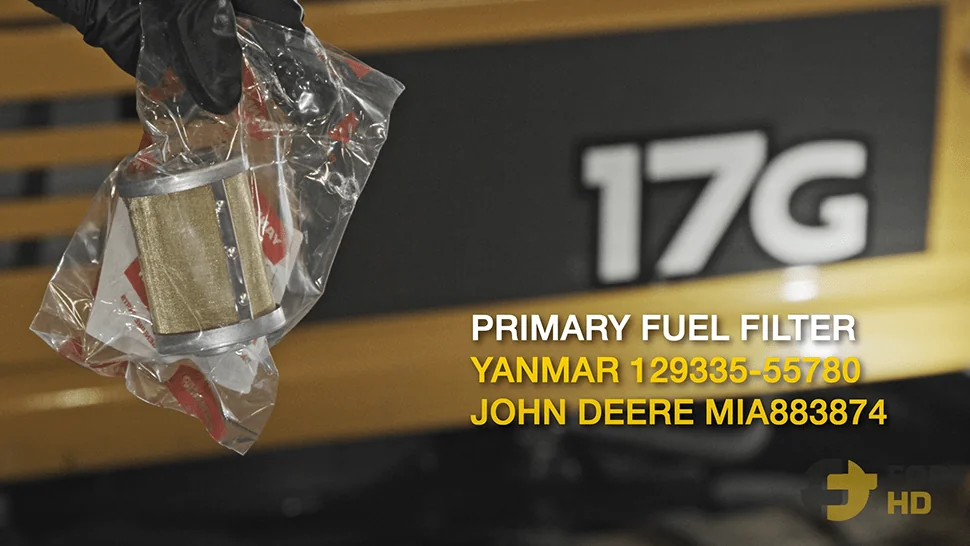

| Primary Fuel Filter | MIA883874 | N/A | N/A | N/A | N/A |

| Secondary Fuel Filter | MIU803907 | N/A | N/A | N/A | N/A |

| 2 x Fuel Filters O-ring | M800893 | N/A | N/A | N/A | N/A |

| Engine Rocker Arm Cover Gasket | MIU800300 | N/A | N/A | N/A | N/A |

| Engine Air Filter | M113621 | RS3715 | P822686 | 46449/46449FR | N/A |

| Air Cleaner Dust Unloader Valve | 4383877 | N/A | N/A | N/A | N/A |

| Engine Oil | TY26674 | N/A | N/A | N/A | N/A |

| Gear Oil | TY6296 | N/A | N/A | N/A | N/A |

| Hydraulic Oil | 2908-050 | N/A | N/A | N/A | N/A |

| Coolant | TY26575 | N/A | N/A | N/A | N/A |

Table of Content

Remove the Water Separator Filter

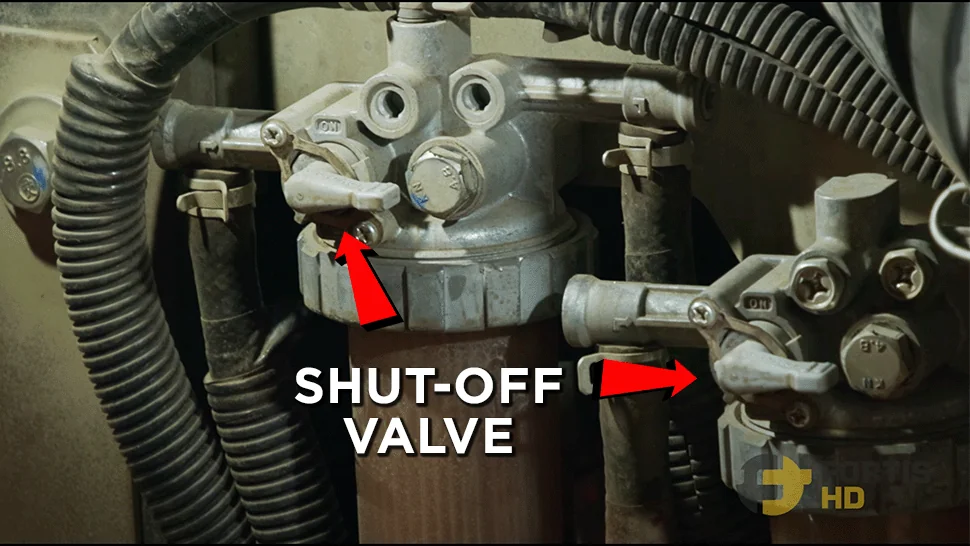

First, open the backside hood and shut off both fuel valves.

Next, remove the water separator housing. There’s a ribbed ring at the top of the housing. There are several ways to get it out.

If you bought the machine brand-new, it could have come with a tool kit to unthread the ring. A filter wrench can do the trick as well. However, due to the lack of space, there’s a chance of damaging the aluminum clamps of the hoses with the pliers.

You can use a flathead screwdriver to remove the ring. Put the head of the screwdriver on the edge of a rib and hit it with your palm or hammer. Give it a couple of tabs (clockwise direction) to loosen the ring and thread it off by hand.

When you pull off the separator, diesel will come out. Put a drain pan underneath to catch the diesel.

Remove the fuel filter and O-ring by pulling them off.

Dump the fuel from the separator, and take out the spring and red ring. The ring floats on water and sinks in diesel (when water builds up, the ring floats so you can monitor how much is in the system). We recommend draining the separator daily.

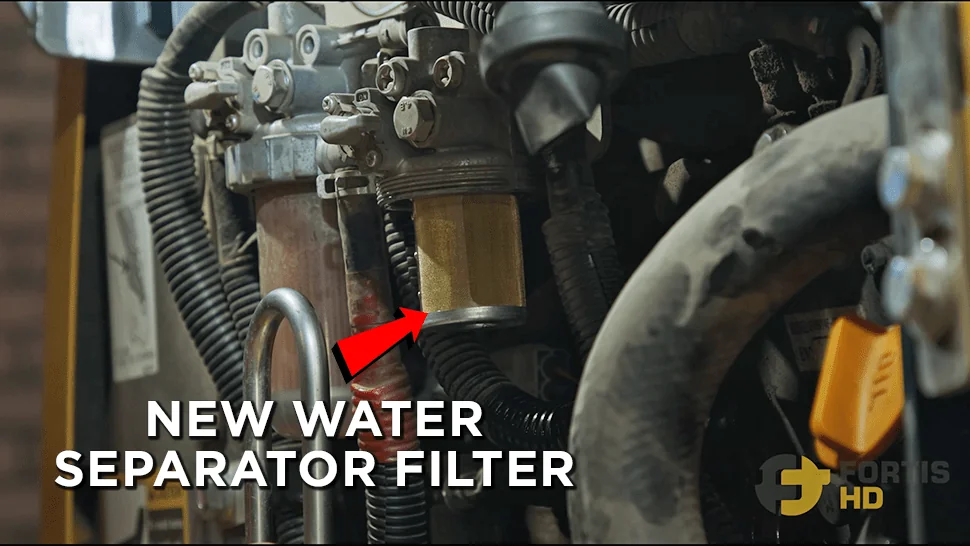

Install the New Water Separator Filter

Use a brake cleaner to thoroughly clean the plastic canister, the ring, and the spring.

Put back the ring, making sure it sits flat on the bottom of the plastic canister. Also, put back the spring, ensuring it sits on the top of the bottom nipple.

Install on the new filter, applying some up pressure (it’ll stay there).

Lubricate the new O-ring (just rub it with a bit of oil) and put it on top of the water separator plastic container.

Slide the plastic container through the ribbed ring and put everything up in its place. Before threading the ring, ensure the O-ring sits evenly. You can tighten the ring using a flathead screwdriver (the same way you took it out, but counterclockwise).

Replace the Fuel Filter

The process is the same as with the water separator. Unscrew the ribbed ring of the canister using a flathead screwdriver (give it a few taps clockwise direction).

Take out the canister and the old filter. Dump the fuel from the canister and clean it thoroughly with a rag and brake fluid.

We recommend replacing the O-ring every time you change the filter. Lubricate the O-ring to ensure a proper sealing surface.

Because there’s little room on this machine model, drop the new filter partways into the housing when pushing it up in its place (the filter will hold itself on). Put back the canister making sure the seal sits correctly. Screw the ring by hand and tighten it with a few taps using the screwdriver.

Changing the fuel filters makes air enter the system. We must remove it because the 17G has a diesel engine system that won’t run with air inside. .

First, turn back on the fuel valves, then turn the key on for about 3 minutes to make the electric pump send fuel through the system. Fuel will push the air out of the filters and into the tank.

Start the machine and give it a bit of throttle to get the rest of the air out of the system. Once the engine runs smoothly, turn off the machine.

Next Post

In part 5, we’ll show you how to clean the radiator of the John Deere 17G Mini Excavator.

If you’re doing this service yourself, visit FortisHD to purchase a service kit with every filter you need, or visit Tekamo HD to hire an expert service technician.