Inside the hatch within the excavator, you will see a part that has a red ring inside as the part is filled with a mixture of water and fuel. This part is a water separator fuel filter. It catches the water and other impurities that may be present in the fuel tank or the line. Since water sinks and fuel rises, the fuel will enter the engine compartment while the water will stay down inside the separator.

In time, the water needs to be drained and the screen replaced during maintenance. Learn how to drain the water separator and replace the screen on a John Deere 35G excavator with our following maintenance guide. You can also use these steps for other mini excavator brands, such as on a Caterpillar, Volvo, CASE and Komatsu.

Excavator Maintenance For Heavy Equipment Mechanics

Table of Content

Step 1: Check Water Level

You will notice a red ring inside the water separator. This ring tells you how much water is inside as it rises. If there is water in the separator, you’ll have to drain it before replacing the screen. You’ll need a small hose and drain pan as you want to push the hose onto the drain.

Step 2: Leave Fuel Valve on If Draining Out Water

If there is water present, leave the fuel valve in the ON position at the top of the water separator. Open the valve on the drain by simply unscrewing it slightly. You don’t have to completely take the valve off. Only a small amount of fuel may come out as it mixes with the water. Yet mostly water will escape first.

After all the water is drained, fuel will start to enter the hose. Screw the valve closed to stop the fuel drainage.

Step 3: Turn Fuel Value Off to Drain Fuel in Separator

Once all the water is drained, or if there is no water present when performing maintenance, turn the fuel valve to the off position so no fuel enters the separator from the fuel tank. Unscrew the drain valve. If no fuel comes out, crack open the water separator by using a pair of pliers. By slightly unscrewing the water separator, air enters as it creates pressure and forces the fuel to drain.

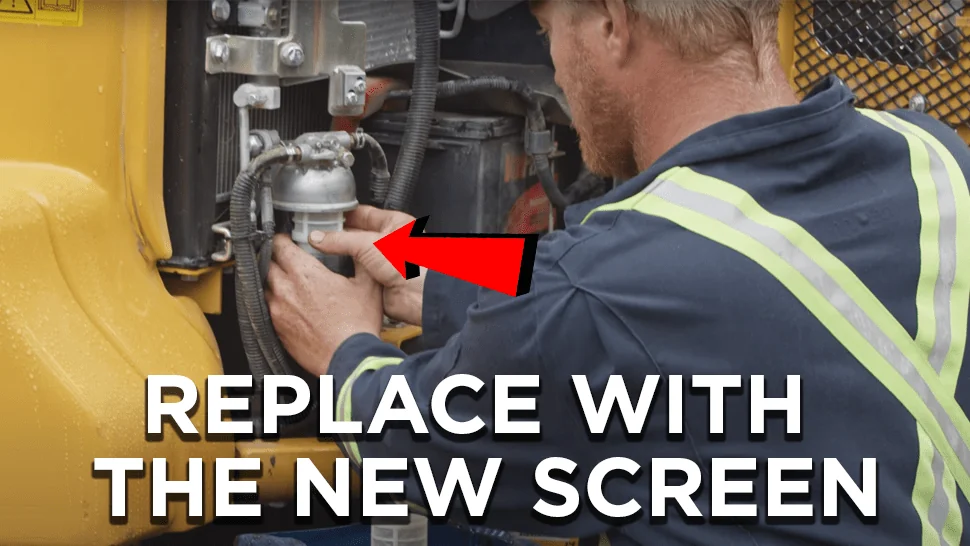

Step 4: Change the Screen

Once it is completely empty, pull the water separator off the machine. The screen inside can be popped off. Put the drain valve back on so as to prevent it from getting dirty. Clean out any crud that is found inside the separator housing. The new screen has two pieces that simply click together. Push the screen back into place on the machine and thread the separator housing back on. Hand tighten the housing so as not to damage the threads.

Step 5: Open Bleed Screw

Once the separator is in place, open the fuel valve. Above the fuel valve is a bleed screw that will allow the fuel to flow back into the water separator. You will need a 10mm socket wrench to loosen the screw for a John Deere 35G excavator. After the fuel has entered the separator, tighten the bleed screw and wipe away any excess fuel from the excavator using a clean rag.

![]()

You are now finished with draining water and replacing the screen on a water separator fuel filter. If you are looking for more details about servicing excavators, contact Fortis HD.