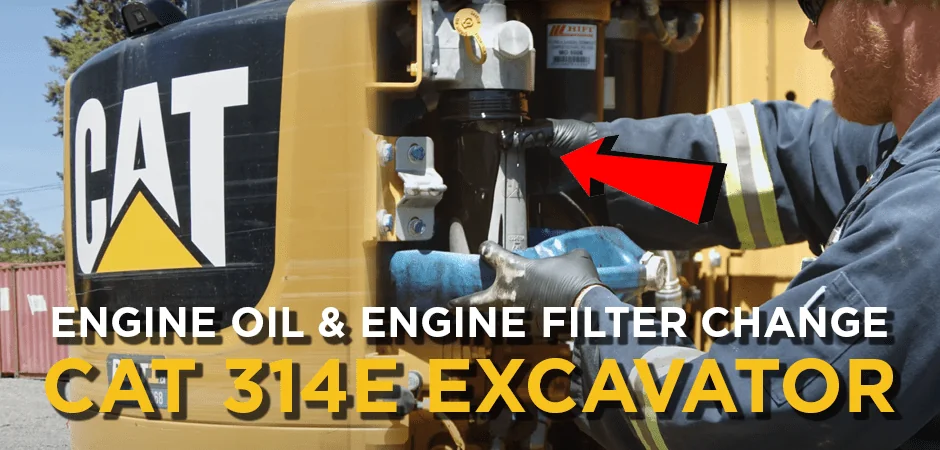

The performance of a CAT 314E excavator and other heavy equipment depends heavily on the engine. For the engine to work optimally and serve you for years without breaking down, it has to run on clean engine oil.

Here is a step-by-step process detailing how to drain engine oil, change the engine oil filter, and replace the engine oil with clean oil from a CAT 314E excavator. However, you can use these steps also to service any other excavator or heavy machine, such as a Hitachi or Volvo machine.

Table of Content

Step 1: How To Drain The Engine Oil

The first thing you want to do is to remove the belly pan underneath the machine. You can skip this step if your machine has no belly pan.

Locate the belly pan and unscrew the bolts. Some machines have four bolts, others might have six bolts or more. In our case, the CAT 314E has four bolts. Two of the bolts that are further in the bolt holes are slotted, so you don’t have to remove them. Simply loosen them. Remove the other two bolts, then slide the belly pan to the front to remove it. The slotted holes also make installation super easy. You simply slide on the belly pan to the back and then screw in the bolts without having to hold the heavy belly pan. Easy right?

In some models, however, all the bolts are tightened and there are no slotted holes so you have to unscrew all the bolts.

The next thing is to get a bucket and place it underneath the engine to catch the dirty oil so that you don’t create a mess on the ground. Have a spare bucket next to you just in case the first one is filled up and there is still some more engine oil to be drained. Some machines drain more than others.

Now it’s time to reach for the engine. On the CAT 314E, there is a small ball valve on the hose attached to the engine. On other machines, there might be a drain plug right on the bottom which you’ll have to remove first.

Be careful when removing the drain plug because as soon as it’s out, the oil comes out right after. So you want to be quick in placing the bucket.

In our case, we will put an empty bucket right under the hose pipe, then opened the ball valve to release the oil. You may have to unscrew the ball valve a few times to drain oil faster. Ensure that all the oil drains into the bucket.

Once all the oil has been drained, close the ball valve and put the belly pan back up. Make sure the ball valve is well tightened. You can use pliers to help tighten it. Just don’t go overboard with the tightening.

Step 2: How To Change The Engine Oil Filter

To change the engine oil filter, you first have to remove the old one. So start by removing the piece under the filter housing. Use a wrench or a socket in a bigger ratchet to loosen it then remove the piece by hand. Immediately put the drain pan underneath the filter housing to catch the dripping engine oil.

While holding the drain pan with one hand, remove the filter with the other and set it aside. Be careful with the balancing not to create a mess. Leave the drain pan on for a couple more minutes to allow all the oil to be completely drained.

Now it’s time to replace the engine oil filter. Unwrap your new filter and using your finger, take a little oil from the filter housing and wipe it on the ceiling part of the gasket. Just a little bit to lubricate it enough to make threading easier.

Thread the filter into the housing. You can go as tight as possible so that there is no chance of oil leaking. Tighten it from the bottom using a wrench until you feel it can’t go anymore.

This process works for all machines with canister-style engine oil filters.

Step 3: How To Refill The Engine Oil

Time to refill the engine oil in our CAT 314E. So first off, open the hood of the engine and locate the engine fill. In some models, the engine fill will be located on the side but in the CAT 314E, it’s right at the top of the valve cover.

Take a funnel and place it carefully so that it doesn’t tip over and create a mess. Next, take the engine oil. We used the 15.40 mineral oil but if you have a different model, you may want to check with your manufacturer to confirm which oil specs suit your machine.

Fill the engine oil but don’t do it too fast. Take it slow with a minute break in between the filling to allow the fuel to go down otherwise, it will spill into the intake system and cause the machine to fail when you start it. This is particularly common with the Hitachi 75.

Be sure not to overfill the engine with oil. The best way to know how much oil your engine needs is to use the dipstick. Every machine comes with one. You want to be within the recommended gauge, not too low or too high up. Check the dipstick as many times as possible until you get the right range.

You can also judge the amount needed by the amount you drained from the engine. So for instance, if you drained half a bucket of oil from the engine, then you obviously need to replace half a bucket of clean oil.

But remember, we just replaced the engine filter so when you start the engine, it will suck up some of the engine oil and the level will go down. So for an accurate reading, we will have to start the engine, let it fill up, and check if there are any leaks before we decide if that’s enough oil or we need to add some more.

Put the dipstick back in, remove the funnel, close the engine and the hood then start the engine for just a few seconds. Five to ten seconds tops.

If you hear a buzzer go on, just ignore it. There is no cause for alarm. That’s just an indicator that the engine oil pressure is low. It should turn off again once the engine oil filter is filled up and there is enough pressure in it.

With the engine filter filled up with oil, its time to double check the engine oil recordings. So once again, open the engine and insert the dipstick. If you find that the oil is a little on the low, add some more. Be sure to use a clean funnel so you don’t accidentally contaminate the engine. Keep checking the recordings with a dipstick until it gets to just slightly below the high mark. This should be sufficient to run the engine without worrying about the engine oil running low.

Put the dipstick back in, remove the funnel and put back the engine cap to close the engine oil fill. Finally, close the engine hood.

![]()

|

Want to know more about heavy equipment maintenance? Check out our article on how to how to change the CAT 314 Air Filter. |