Although not an everyday tool, an air hammer helps you do certain heavy-duty tasks easier and faster on trucks, agricultural, and construction vehicles. You can quickly loosen tight connections, split final drive housings, drive out pins from dozer equalizer bars, or remove kingpins without the need to assemble a press kit.

Is this your first time looking for an air hammer? Let’s break down basic topics to guide you on your next purchase.

Not your first rodeo? Then, skip to this section, where we’ll show you one model above everything else, no matter how big or nasty they are.

Table of Content

What Is an Air Hammer?

Air hammers get power from a compressor, which delivers air via a hose feeding through an inlet. The air goes into a barrel, moving a piston back and forth rapidly, where the hammering action takes place.

Air hammers deliver high-energy blows at a rapid pace, which is physically impossible to do with a regular hammer. Besides, pneumatic hammers get rid of the need for swinging space and aiming. Simply put the bit against what you want to beat and press the trigger.

Some models have a ‘’throttle regulator’’ to control the air volume inside the barrel to hammer at different speeds to switch between precision or heavy-duty jobs.

What Can You Do With an Air Hammer?

Air hammers are versatile tools thanks to all the bit types available. The basic bits are blunt hammers, punches, chisels, and cutters.

Many variations and attachments exist for further versatility, like soft hammers (brass, aluminum, and nylon), sockets, and torx bits. There’s even a needle scaler to knock chunks of rust from metal surfaces.

Some air hammers support pullers, which revert the force direction to pull instead of pushing, turning them into slide hammers.

Depending on the bit, you can quickly clean rust, cut exhaust pipes, drive out pins and bushings, split ball joints, remove wheel bearings stuck in the hub, and break loose seized fasteners or rusted screw connections.

Choosing the Right Air Hammer

Let’s compare the different features of pneumatic hammers so you can choose the best fit for your needs.

Overall Considerations

Some specs most brands highlight in terms of performance are the length, the BPM (blows per minute), the CFM (cubic feet per minute), and the required pressure.

The length of the hammer links to its stroke length—which in turn links to the power—and the blows per minute. Long barrels can have larger, heavier pistons and more acceleration time, thus producing more power with fewer blows per minute. On the contrary, short barrels have a higher blow frequency but less power.

The CFM and the required pressure are interdependent values related to the performance of the hammer and the air compressor.

Pneumatic hammers need a continuous air flow at a given pressure to operate efficiently. When choosing one, make sure your compressor meets or exceeds the CFM and PSI requirements of it.

The extra room for some long air hammers allows them to have vibration damping systems— consisting of valves and springs. Small and medium hammers don’t have these systems, so they feel more rowdy. Vibration dampers help reduce user fatigue and the risk of developing injuries in the long run—if you use the hammer frequently.

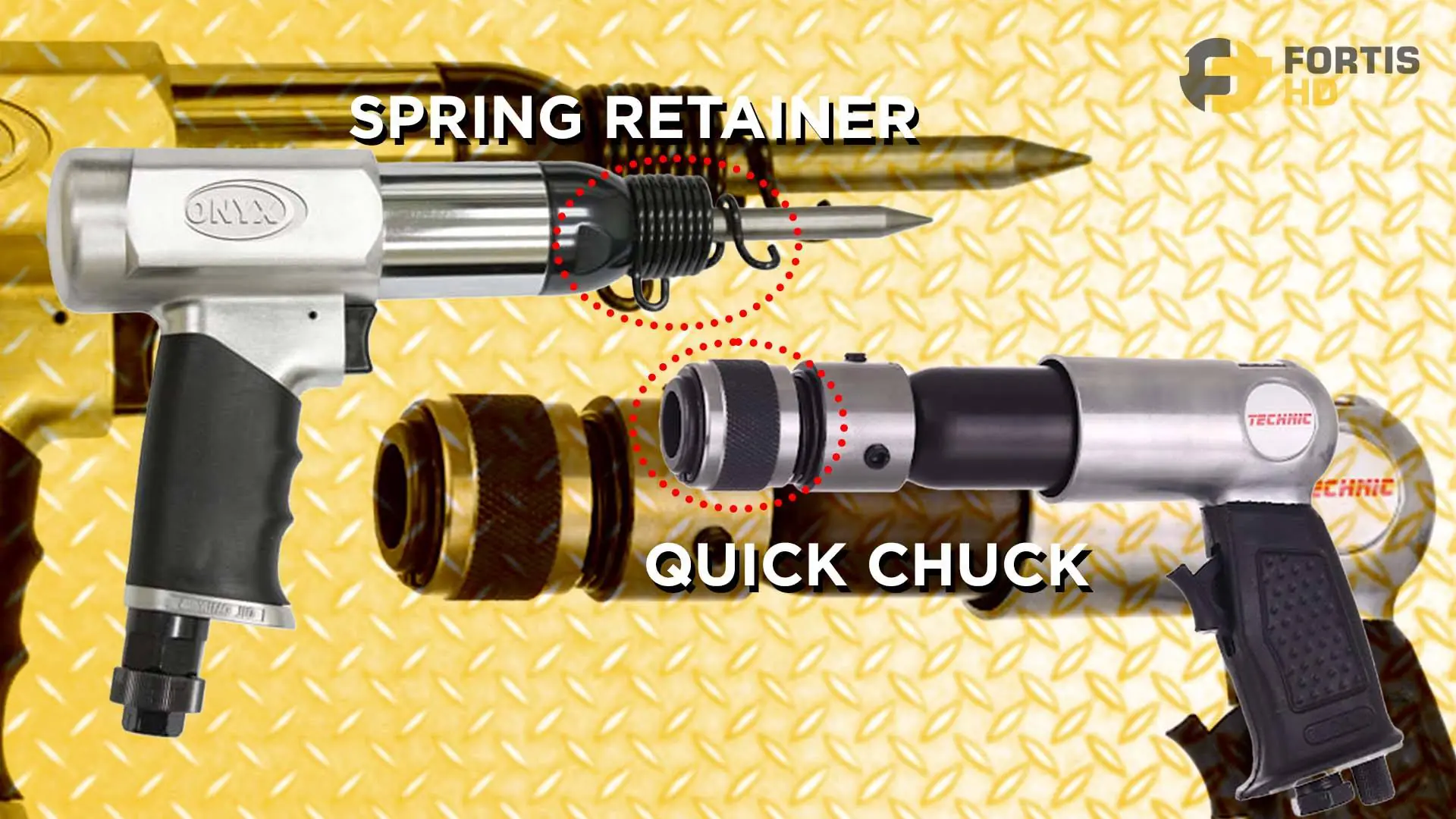

Another discussion topic among mechanics and tool enthusiasts is the bit retainer. You can swap between two types: spring retainers and quick release couplers—quick chuck.

Most air hammer owners find the quick chuck better than the spring. You must unscrew the spring retainer and put it back every time you switch bits. Besides, people like this member of the garage journal forum even complain the bits come out frequently while using the spring retainer.

On the other hand, you just need to screw the quick chuck once, tighten it with an Allen wrench and pull it back to insert or remove the bit.

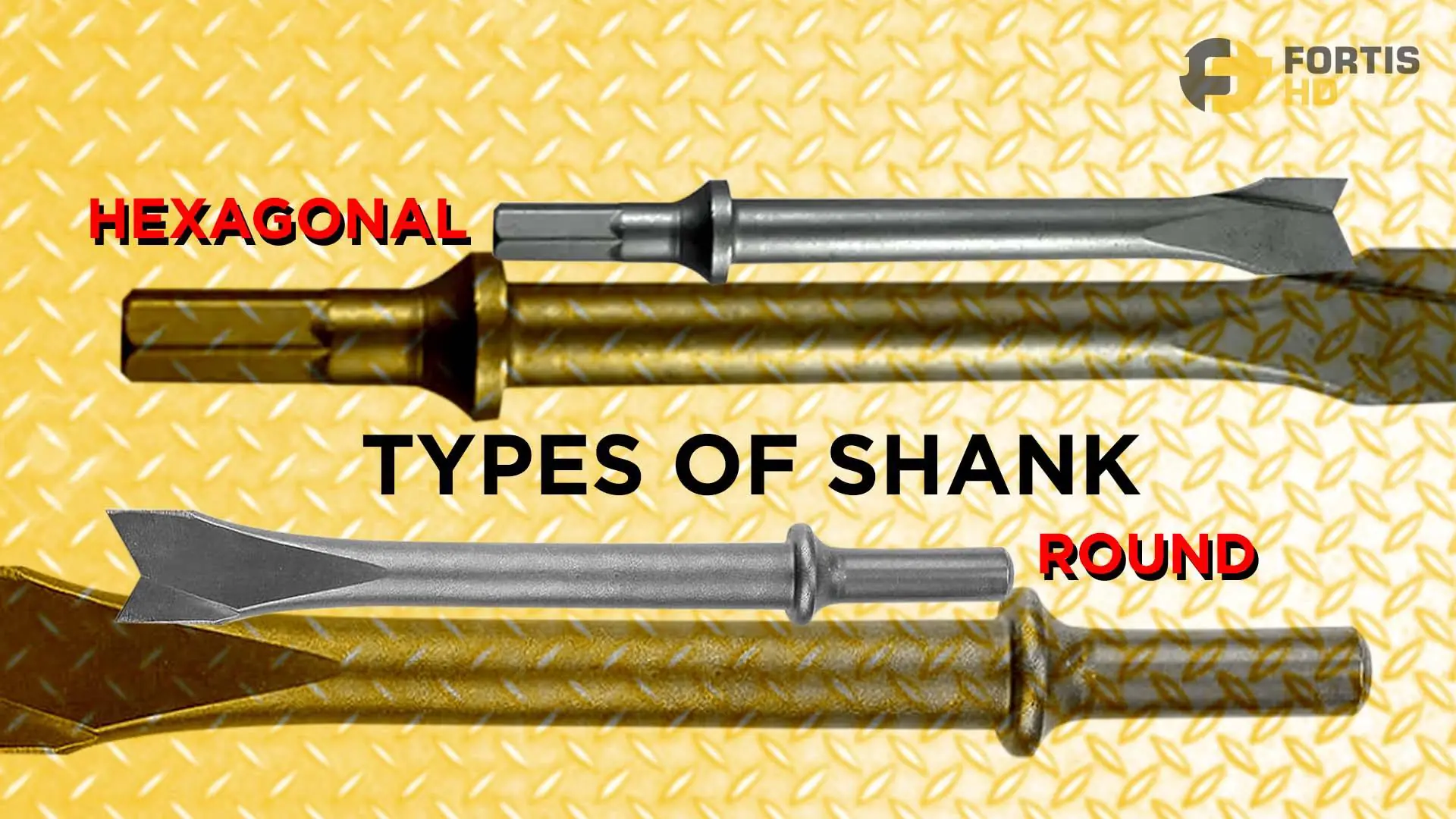

Talking about bits, depending on the design of the hammer, they can use bits with a round or hex shank.

Round shank bits can rotate in the hammer, allowing them to move freely and accommodate curved or uneven surfaces. Hex shank bits are more stable since they don’t rotate in the tool, which is handy for precision and stability.

Before moving to the next section, here’s a brief comment about swivel adapters—a popular accessory for air tools.

Although they help you gain flexibility against the hose resistance, some designs reduce the performance of the hammer, as you can see in the case study: How Much Power Are You Losing w/ Air Swivels? So choose wisely.

Our Recommended Air Hammer

At Fortis, we want to offer you the best tools. Our recommendation? The Mueller Kueps VIBRO-IMPACT Heavy Duty Air Hammer.

According to Andre Van Lagen, Mueller Kueps’ national sales manager of North America, “the vibro impact hammer is four times as strong as the best .401 shank air hammers in the market.”

The hex shank bits keep up with the superior strength of this high performance air hammer. Cam, one of our HD mechanics, says that he’s been beating the snot out of the bits, and there’s no mushrooming on them, and neither chipped.”

As HD mechanics know, regular .401 shank bits end up almost being semi-consumable items in their hands.

What have we done with the Vibro Impact?

- Take out two-inch pins seized in place.

- Split final drive housings.

- Remove track pins.

- Take out equalizer bar pins from dozers.

From disassembling conical seat connections, wheel bearings, and bushings to tackling rusted screw connections, the Vibro Impact Air Hammer is your go-to tool for challenging tasks. The Vibro Impact Hammer is available for purchase on the Fortis HD website.

You can read our in-depth review of the Vibro Impact Hammer in our post “Mueller-Kueps Vibro-Impact Air Hammer: the Big Brother of Air Hammers.”

Or watch Cam’s full review version in the video below:

Safety Guidelines and Maintenance

Before wrapping up, let’s look at some safety measures to reduce the risk of health issues while using your air hammer and how to keep this power tool in peak condition.

Safety Measures

Make sure to put on hearing protection and safety glasses whenever using an air hammer.

Pneumatic hammers are loud. Some manufacturers include the decibel level in their product specs, which ranges between 85 to 100 dB. Levels above 85 dB can cause hearing damage over prolonged exposure.

Besides, air hammers cause bits of material to break off and become airborne. There’s also a risk of the air hammer bit itself breaking or shattering. Both factors pose a significant risk of eye injury.

Maintenance

The compressor draws air from your surroundings, which isn’t 100% clean and has moisture.

The compressed air creates water, and small amounts of it will go in the hose line along with dirt, so we recommend putting a few drops of lubricant—WD-40, Blaster Professional Air Tool Conditioner—in the inlet to keep your hammer lubricated and in peak performance.

Wrapping Up

Air hammers are a top tool. They make things easier, faster, and sometimes even fun. You might not need one as an apprentice, but consider getting one once you gain experience.

Remember, a long hammer equals more power at lower blows per minute, while a short one delivers more blows with less power.

As a seasoned professional mechanic, you must experience the Mueller Kueps Vibro Impact Hammer and its array of equipment like the flat chisel, pin driver, blunt hammer, concave bit, and especially, the tie rod separator.

For our apprentice buddies, before getting the Vibro Impact, check our list of the Top Heavy Equipment Tools you need from the get-go.