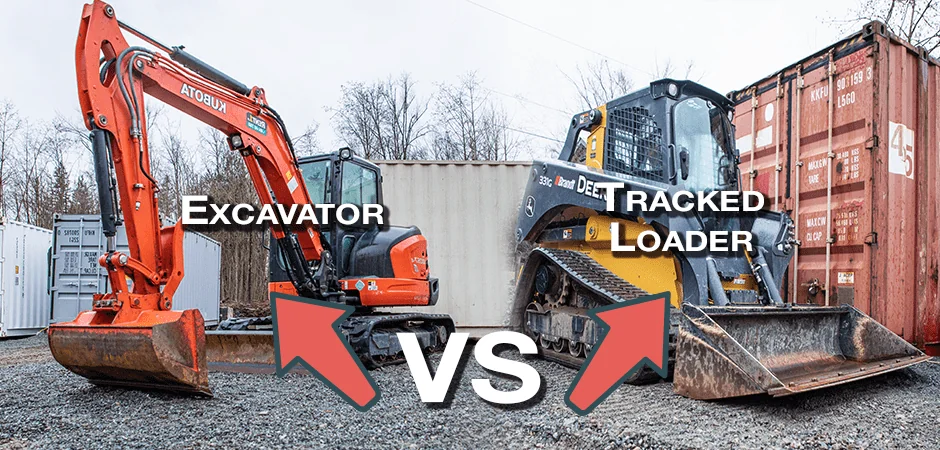

Whether you are working on a farm moving bales of hay or a construction site digging a trench for fiber, you need the right equipment to get the job done. From construction to demolition to landscaping to anything in between, excavators and tracked loaders are two pieces of machinery invaluable to completing a task on time and within budget.

The key to choosing between one or the other is a matter of sizing up each machine’s capability and understanding your job requirements.

Table of Content

Excavator: The All-Purpose Champion

One of the biggest advantages of a compact or mini excavator – the John Deere 35G, Kato 9VX-3, Bobcat E10, Gehl M08 or many others – is there size and versatility. Compact or mini excavators are hugely popular because they can work in places other units cannot – indoors, for instance or other areas with space restrictions.

What is an Excavator?

At its most basic level, think of an excavator as a steel or rubber tracked machine equipped with a blade and independent boom swing. Thanks to advanced hydraulics and quick-change couplers, an excavator can perform a variety of tasks with literally hundreds of optional attachments from original equipment manufacturers and third-party suppliers.

What can you do with an Excavator?

In many cases, a compact or mini excavator is tasked with doing physically intensive or dangerous tasks once delegated to multiple human workers. Now, the same job can be achieved with a single operator. Instead of utilizing a tractor, small truck or pickup, or other machinery, business owners are choosing tough, versatile excavators for the same tasks. Excavators can be used for:

- Agriculture or farm work, including cleaning barns, moving bales of hay, spreading seed, or cleaning out last season’s dead crops.

- Construction sites with limited space. A worksite clogged with cement mixers, dump trucks, stationary waste receptacles, demolition debris, or onsite inspectors, is no trouble for a nimble compact or mini excavator.

- Landscaping services. If you are tasked with clearing and grading a piece of property for a new house, garage, patio, or inground swimming pool, a John Deere 17G is the perfect choice for removing tree stumps, digging, and grading.

- Small-scale civil engineering projects, such as excavating for sidewalks, parking lots, and other hard surface areas.

- The installation of infrastructure projects, such as water and sewer, gas lines, inground electricity, and telecommunications and fiber upgrades.

- Railway work.

- Small-scale demolition projects and debris removal.

- Waste removal projects at community landfills or other locations.

Truly the best thing about a compact excavator is the variety and number of optional attachments available. John Deere, Komatsu, Hitachi, Gehl, Kato, Bobcat, Caterpillar and many other manufacturers try to one-up each other with accessories for specific tasks and industries. The same attachments from different manufacturers work just as well as the competition, but choosing one over the other depends on which brand you have already committed to and invested in already.

The Tracked Loader: A Worthy Challenger

Until recently, a compact or mini excavator was the go-to solution for a wide variety of industries requiring moving earth or debris or performing related chores like excavation and grading. Chances are, if you worked in construction (residential, commercial, or industrial), civil engineering (building or maintaining roads), agriculture, landscaping, demolition, or another heavy machinery-required field, there was a multipurpose excavator nearby. But momentum has slowly begun moving in favor of a similar piece of equipment known as a tracked loader or compact tracked loader.

What is a tracked loader?

It is basically a machine that is moved by a tracked chassis and is equipped with a loader for digging or moving heavy objects as needed. In more broader terms, this machinery encompasses compact skid steers, wheel loaders, and rubber-track loaders.

Many professionals who use a tracked loader, such as the Caterpillar 953K or the John Deere 317G, are attracted to its toughness and versatility. Fully capable to achieve many tasks, a well-equipped tracked loader can never be pigeon-holed as a single-purpose machine.

Historically, the first tracked loaders basically operated as bulldozers. The second evolution involved the application of hydraulic systems and buckets, followed by hydro-static drive systems for more efficiency while in operation.

Why would you choose a tracked loader?

There are different reasons, besides just knowing what tools and machinery are best suited to your job requirements. Whether you encounter a job site with multiple ground conditions – sand, mud, soft, wet, or hard – or weather, there likely is a compact tracked loader that will get the job done. You may decide to go with a tracked loader because:

- The number of optional attachments makes this machine a jack-of-all-trades at any worksite. Each brand offers an array of accessories, including Augers and trenchers; Backhoes (yes – you can equip a tracked loader to function as a backhoe!); Blades and scrapers; Brooms; Buckets; Cutters, shredders, and mulchers; Forks and spears; Grapplers; Hammers; Planers; Rakes and tillers; Rollers; Snow Attachments; and multiple styles of steel and rubber tracks.

- The tasks that a well-equipped tracked loader can accomplish. With the right attachment, there are limitless opportunities to get work done. From digging to trenching to moving earth, debris, or equipment, a tracked loader has few peers. Machines like the Gehl RT165 are well suited to perform tasks handling waste or moving product from docks or loading bays, mixing cement at construction sites, picking up wrapped bales of hay, plowing snow, spreading seed, or many others.

- High-tech innovations and operator comfort. Today’s compact track loaders continue to evolve, with manufacturers committed to features such as in-cab overhead control panels, LCD displays, ergonomic seating, high-efficiency heating and cooling systems, for four-season comfort, heavy-duty drive trains, and engines optimized to squeeze every last mile out of every drop of fuel.

Choosing between an excavator like a John Deere 35G or a compact tracked loader such as the T450 from Bobcat is not a question of which is better, but which is better suited to your needs. So choose wisely, or call us at 855-897-5942 for more information.