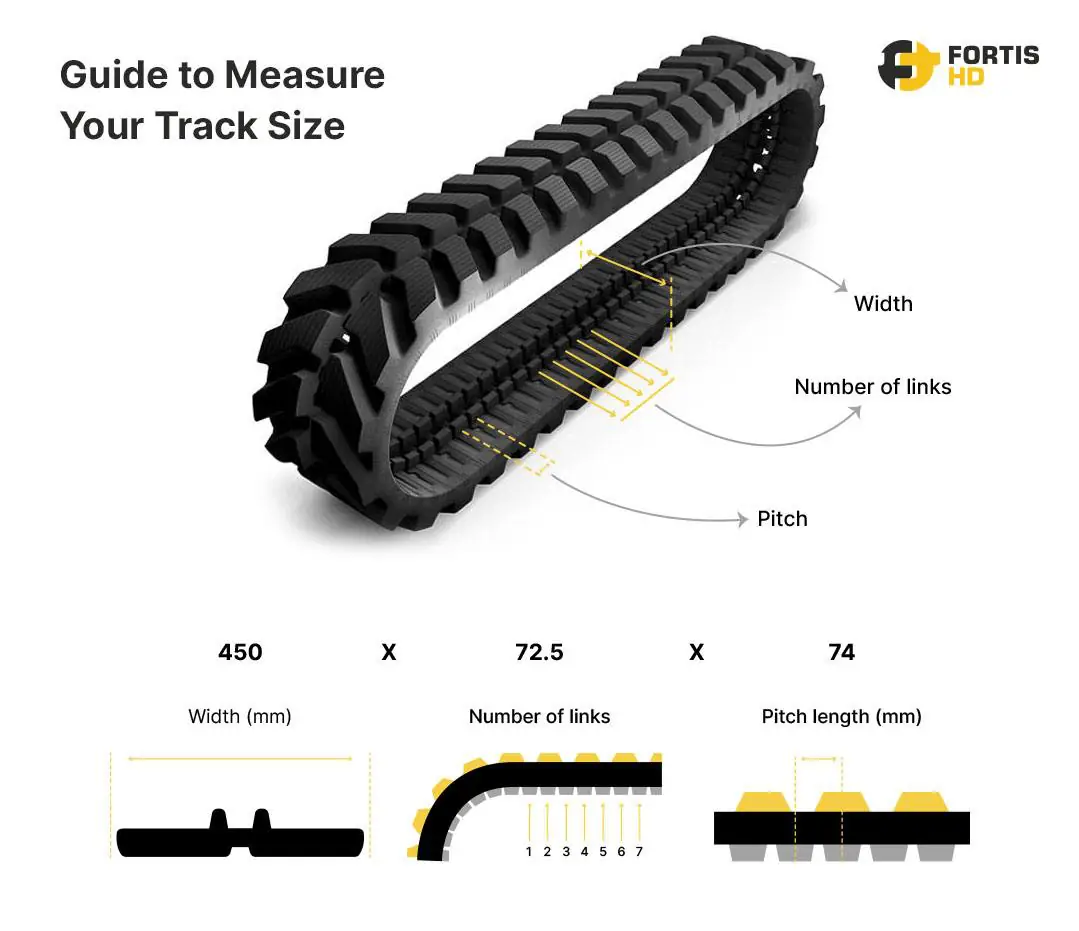

The industry standard for identifying rubber tracks is the width x pitch x number of links.

Here is a quick and easily understandable way to measure rubber tracks for heavy equipment:

However, even if a set of rubber tracks has a width, pitch, and number of links that match your old tracks, you must also consider the track guide and the machine guiding system.

Knowing the size of the guide prevents the rubber track from breaking, jamming, or being thrown from the undercarriage.

Although you can tell the guide type (and other features) from the letters in the rubber track size number, each manufacturer has its own identifying system. Luckily, some manufacturers share similar ID conventions.

We’ll share with you the meaning of some of those letters, but to better understand them, we’ll first talk about:

- The link between the track guide and the undercarriage guiding system.

- The types of rubber track guides.

- The types of bottom rollers in the undercarriage.

Let’s break down everything revolving around the letters in the rubber track size.

The Link Between the Track Guide and the Undercarriage Guiding System

The guide is the part on the rubber track interlocking with the sprocket, idlers, and rollers, which comprise the undercarriage guiding system. If you wish to know more about the mechanism of the undercarriage, check out our articles:

- Undercarriage Parts: The Key to Keeping Your Heavy Equipment Running Smoothly

- Understanding the Undercarriage of Heavy Equipment

The track guide and the undercarriage guiding system provide efficient traction, stability, and flotation to the heavy equipment as long as they are compatible.

If you’ve ever interchanged or had a new set of tracks with the right size (width x pitch x links) but wouldn’t stay on, eating away at your sprockets or rollers or riding too rough, there was a guide lug incompatibility.

An example of incompatibility is using inferior conventional tracks on many Yanmar and Kubota excavators.

Versatile across various equipment types and brands, standard tracks will fit but fail prematurely on some Yanmar and Kubota machines because the bottom rollers will quickly eat the rubber compound from the guide lugs, causing rust on the embeds or link ejection.

Many Kubota and Yanmar Excavators need “K tracks,” with a reinforced outer rail track to match their unique rollers system.

The types of Rubber Track Guides

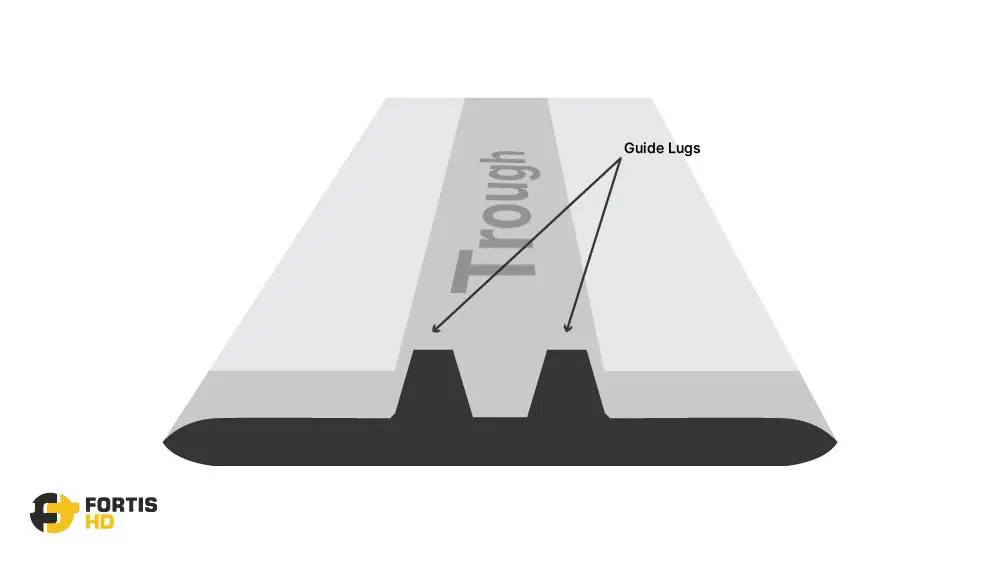

The guide comprises the links and the trough running in between the links.

The links guide, drive, and even add structural strength to the rubber track, depending on its core type.

There are two types of rubber track cores: metal and non-metal.

The metal links are one of the inner components of metal core rubber tracks, contributing to the track’s structural integrity and helping to spread the loads evenly on the ground.

The non-metal core tracks have an inner kevlar reinforcement, and their drive lugs extend from the rubber compound.

Based on the distance between the drive lugs, we can classify rubber tracks as narrow guide tracks and wide guide tracks.

The guide width is one of the characteristics that the letters in the track size number describe.

Narrow guide tracks have a path ranging from 10 to 30 mm and are common on light machinery with compact undercarriages.

On the other hand, wide guide tracks have a path ranging from 40 to 60 mm wide or more. We can find wide guide tracks on heavier machines that require mode stability and load-bearing capacity.

But there’s something more.

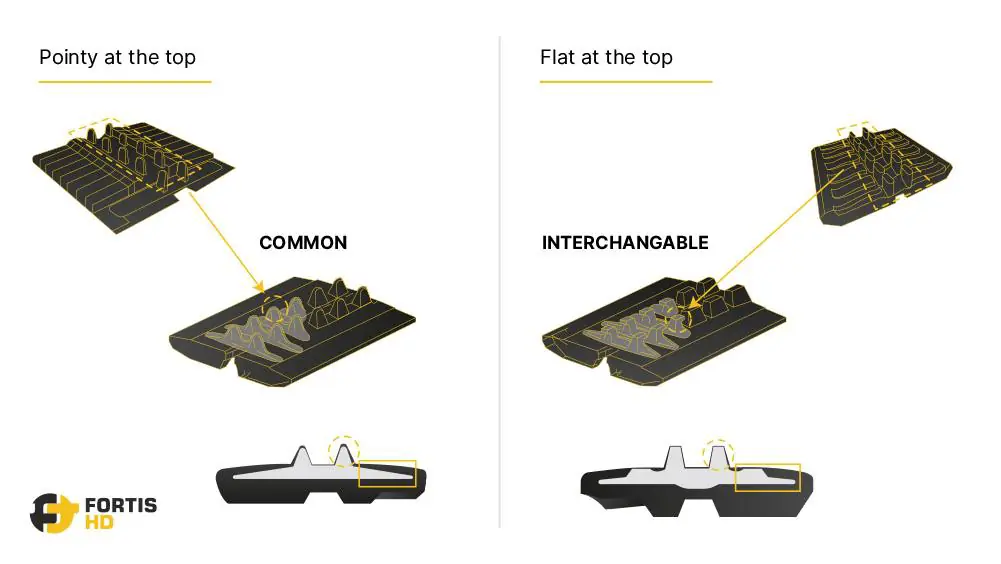

Rubber track guides can be conventional or interchangeable.

The guide is an essential aspect related to the type of bottom rollers in the undercarriage and is another piece of information that letters in the track size number can tell us. We’ll dive deeper into the bottom rollers in the next section.

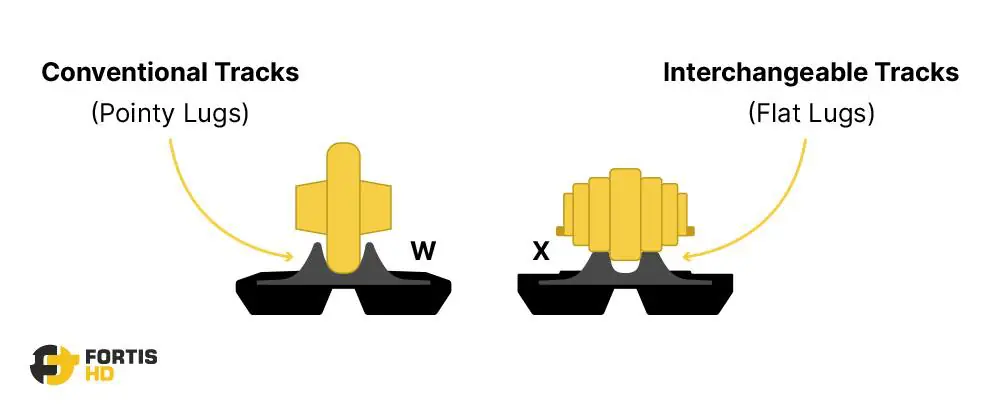

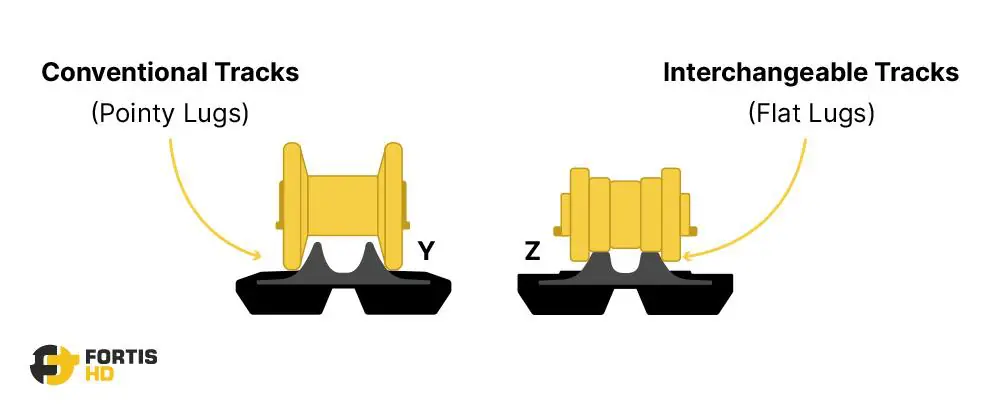

On conventional tracks, the bottom rollers don’t run on the embeds of the rubber track as they do on a steel track chain—the rollers run directly on the rubber body (carcass), and the tall, pointy embeds assist in preventing derailment.

Another conventional style roller design has the roller running down the center of the embed only.

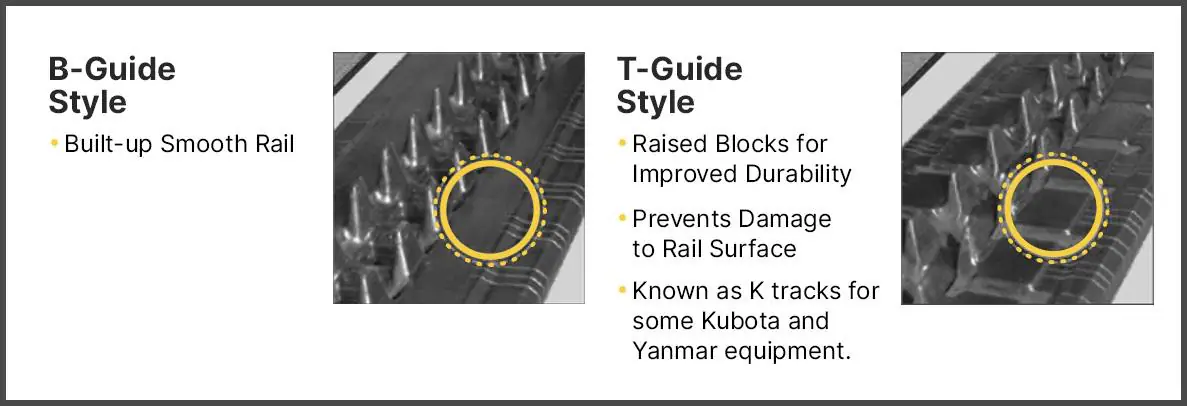

Some conventional rubber tracks will have guides with a built-up platform supporting the machine’s weight and creating the constant flat surface the rollers need to run smoothly.

Depending on the machine brand and the track manufacturer, the guide rail platform can have an identification letter in the track size number.

On the other hand, interchangeable tracks have shorter, flat embeds where the rollers run. There are three types of interchangeable rubber tracks based on the undercarriage rollers:

- Inner guide.

- Outer guide with rollers running on the lugs.

- Outer guide with rollers running on the carcass.

The steel links’ flat design makes the rubber track act like a steel track link, allowing you to use interchangeable rubber tracks on a steel track-designed undercarriage.

The Types of Bottom Rollers

Because some 300 and 400 mm wide rubber tracks can fit inner and outer rail bottom rollers, suppliers could ask about your track rollers depending on your machine model.

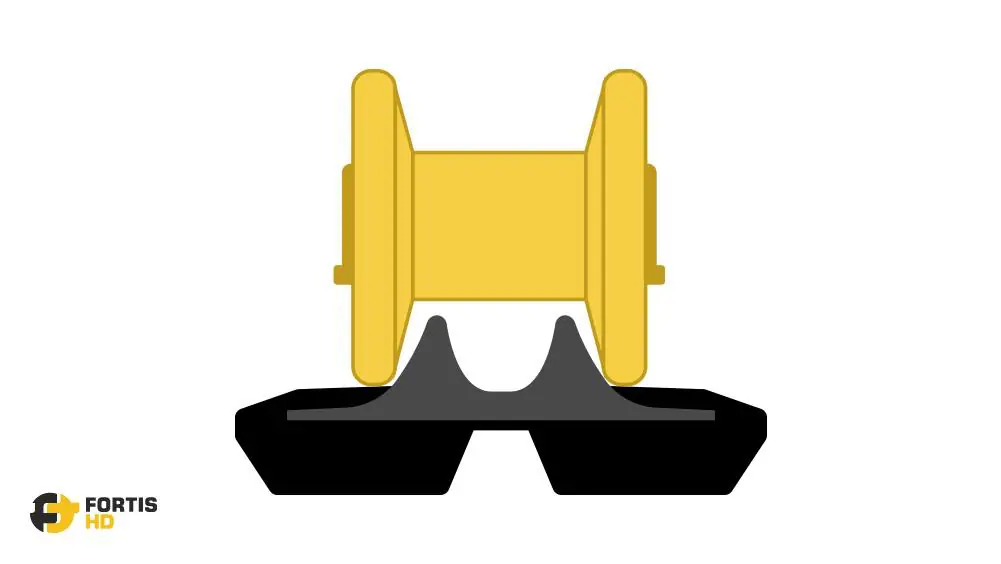

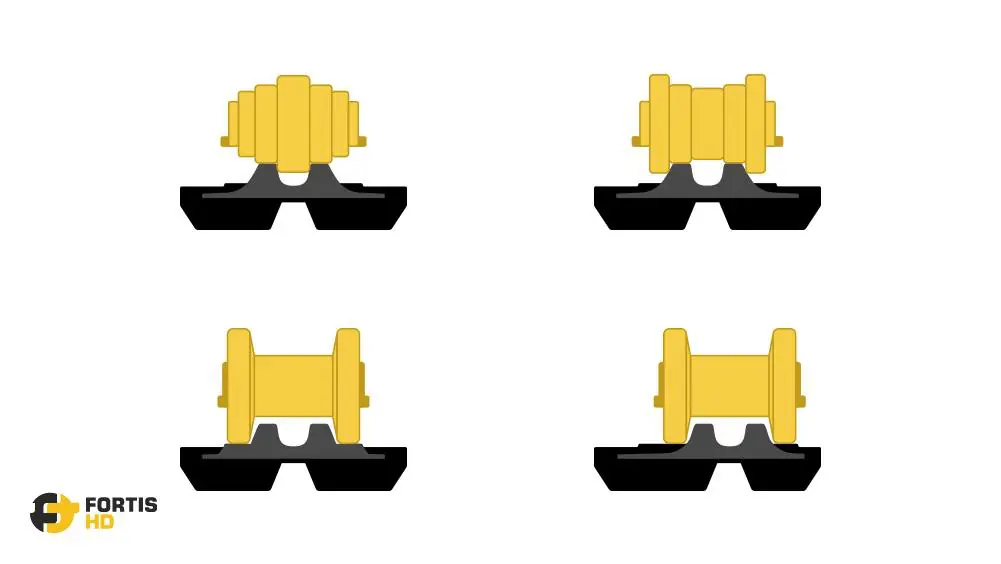

The two major bottom roller types are center (non-rail) and outer (rail).

Center rollers fit between the guides of a rubber track. They ensure the track remains in the correct position, reduce the risk of derailment, and evenly distribute the machine’s weight.

Typically smaller in diameter, you can find central rollers on mini excavators and compact track loaders.

The center rollers for conventional rubber tracks are usually known as “W” and “X” for interchangeable tracks.

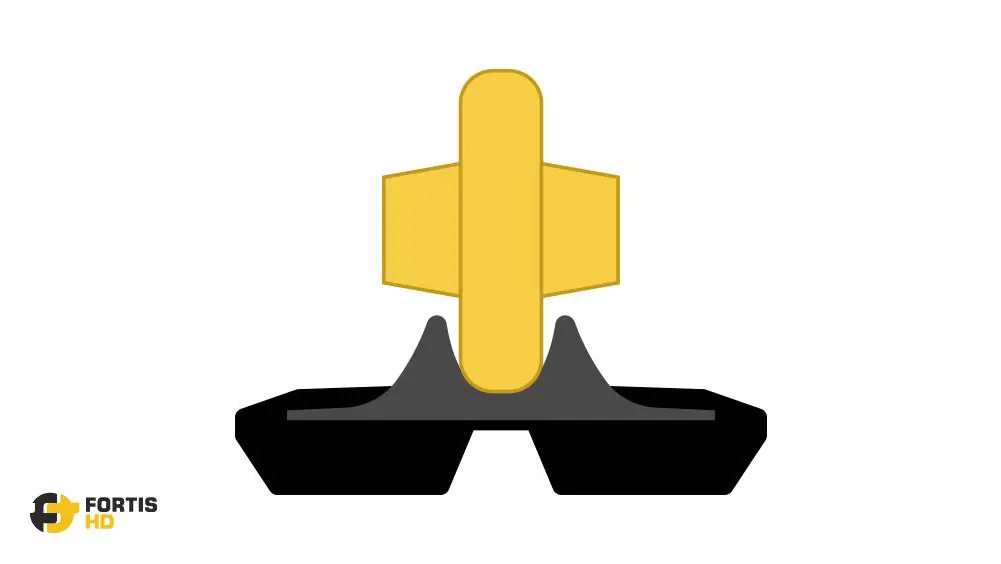

Outer rollers come with flanges to provide lateral support to the tracks, preventing them from slipping sideways off the undercarriage. Outer rollers are essential in applications with frequent lateral forces, such as on slopes or uneven ground.

Larger in diameter, they provide side support to the tracks on heavy-duty equipment like bulldozers and excavators operating in challenging terrains.

Outer rollers run along the outer side of the rubber track guides. The outer rollers for conventional rubber tracks are called “Y,” and for interchangeable tracks, “Z.”

Below are the most common types of heavy equipment bottom rollers.

Center roller (running on the links) for conventional tracks.

Outer roller (running on the carcass) for conventional tracks.

Inner roller for interchangeable tracks.

Double-flanged outer roller for interchangeable tracks.

Outer roller for interchangeable tracks.

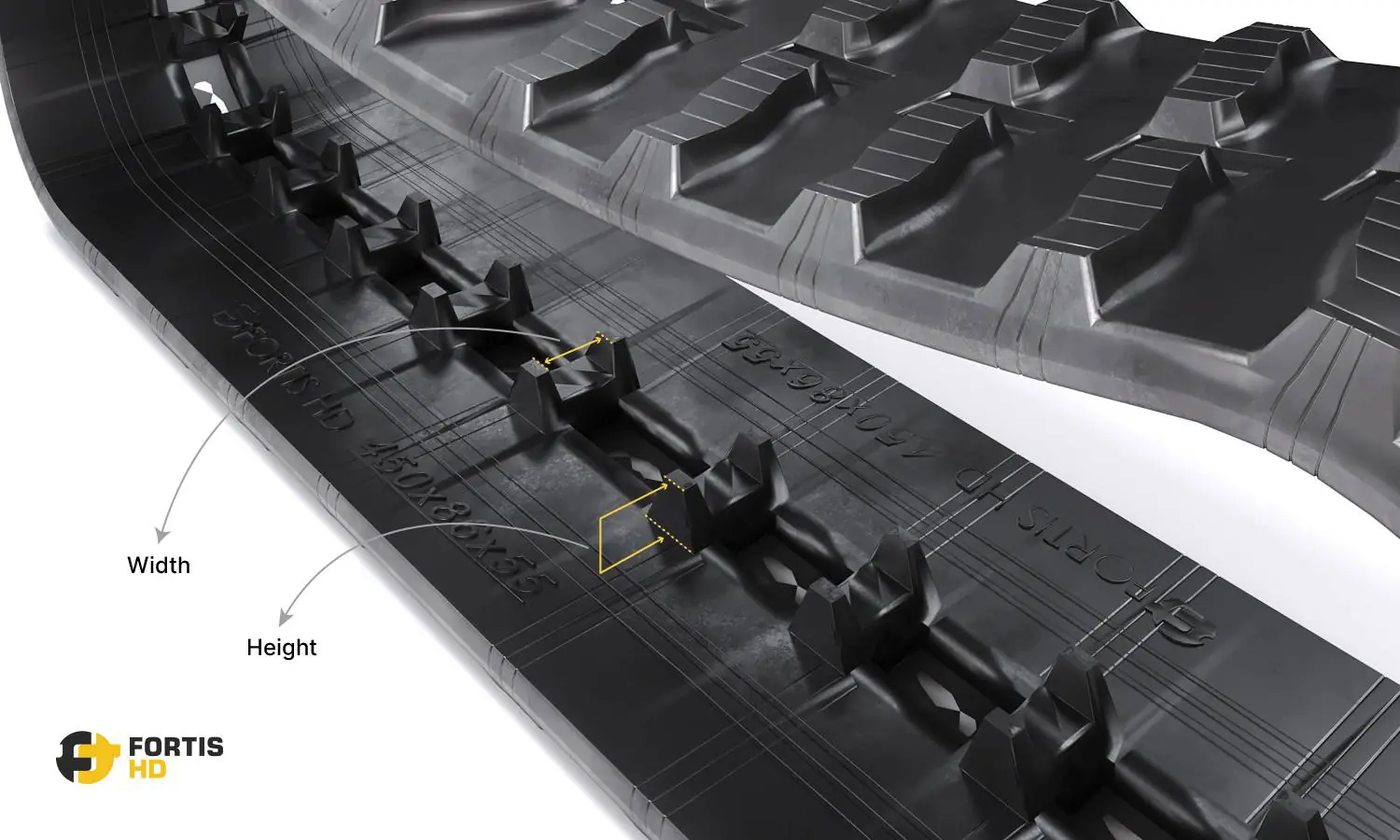

How to Measure Your Guide Size

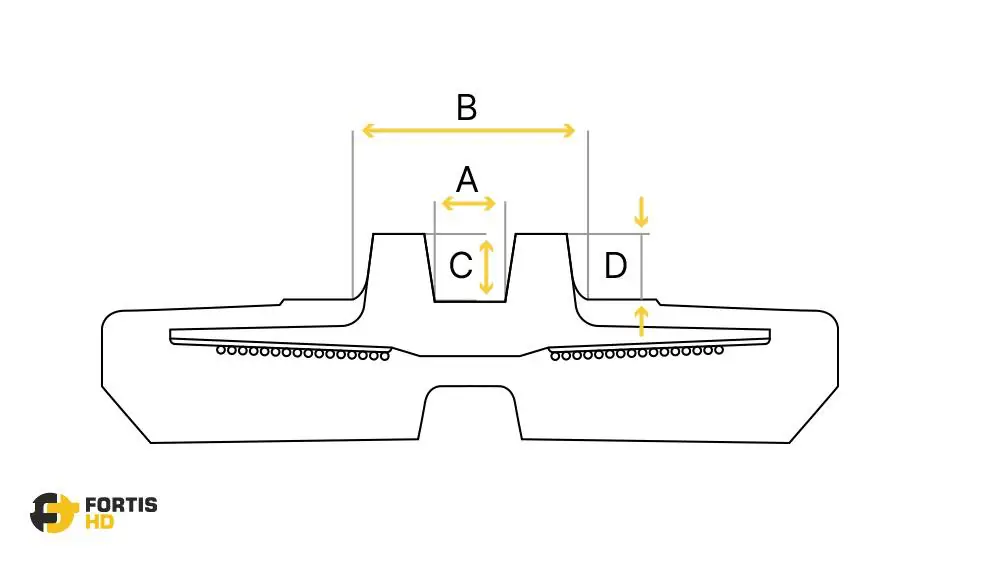

For those of you with 300, 350, 400, and 450 mm wide rubber tracks, besides knowing the track width, pitch, and the number of links, you should also measure (in mm) the guide lugs.

Measure the following:

A = Inside guide bottom.

B = Outside guide bottom.

C = Inside height.

D = Outside height.

Meaning of Letters in the Rubber Track Size Number

As mentioned above, although manufacturers identify their tracks differently, some letters in the rubber track size share the same meaning. You must refer to your supplier for detailed and accurate information.

The letters can be anywhere in the size number, though you can generally find them in the pitch section or at the end of the number.

You can tell the following characteristics from the letters:

- Recommended machine brand to install the tracks on.

- Track quality.

- Type of internal components of the track.

- Track tread pattern.

- Guide width.

- Type of rail platform.

| P | Premium quality. |

| R | Rugger economy quality. |

| J | Jointless cable reinforcement. |

| N | Narrow guide. |

| W | Wide guide. |

| B | B-guide rail style. The rail platform has a built-up rubber section. |

| T | T-guide rail style. The rail platform is reinforced with steel for the rollers to ride on (Takeuchi, Gehl, Mustang CTL). |

| K | Outside roller/narrow guide. |

| KW | Outside flanged roller w/wide guide. |

| C | C lug tread pattern. |

| W | Zig-zag tread pattern. |

| MB | Multi-bar tread pattern. |

| H | Higher C tread pattern (only on John Deere skid steers). |

| ST | Standard tracks. |

Check out the Fortis HD rubber tracks section, where you can buy high-quality replacement tracks for the most popular brands and models. We guarantee our rubber tracks for 100% fitment and to comply with OEM specifications.