Broken glow plugs are a frequent and variable issue. They seize up and snap off at different spots.

There are several DIY solutions to remove the broken, seized pieces, like soaking them in break cleaner overnight, running your car until it reaches a certain temperature to loosen the stuck parts, etc. The thing is, those options take too long and won’t guarantee you’ll solve the problem.

In this article, we’ll show you how to remove broken glow plugs quickly, safely, and like an expert with the right tools:

Table of Content

The Possible Broken Glow Plug Scenarios

There are two possible negative scenarios when trying to remove a glow plug:

- The metal shell breaks above the threaded part.

- The glow plug comes out, but its tip snaps off.

Both result from corrosion or carbon buildup, which seizes the threads of the shell body or the glow plug’s tip.

Besides carbon buildup, the high temperatures of glow plugs cause their tips to expand and sometimes swell, seizing them up in their seats.

Here’s how you should approach each case.

The Glow Plug Broke Above the Thread

You tried removing a stuck glow plug and snapped off the shell between the nut and the thread.

The idea here is to use our Broken Glow Plug Removal Tool to drill the glow plug–shredding it– just below its threaded part without damaging the thread of the engine cylinder head. Then, you’ll use the tap and extractor to take out the rest of the glow plug.

The kit in this post works for M10x1 glow plugs, though the process is the same for other sizes. The M10x1 kit comes with the following tools:

- 3 x twist-off electrode extractors for a 1/4‘’ drive ratchet. Twist-off socket sizes:

-

- 3.5 mm.

- 4.5 mm.

- 8.25 mm.

- 1 x 9 mm x 180 mm, TIN-coated, left-hand drill.

- 1 x M7, TIN-coated, left-hand spiral point tap.

- 1 x M10x1, TIN-coated tap.

- 1 x M7x120 mm, left-hand extractor.

- 1 x slide hammer adapter.

-

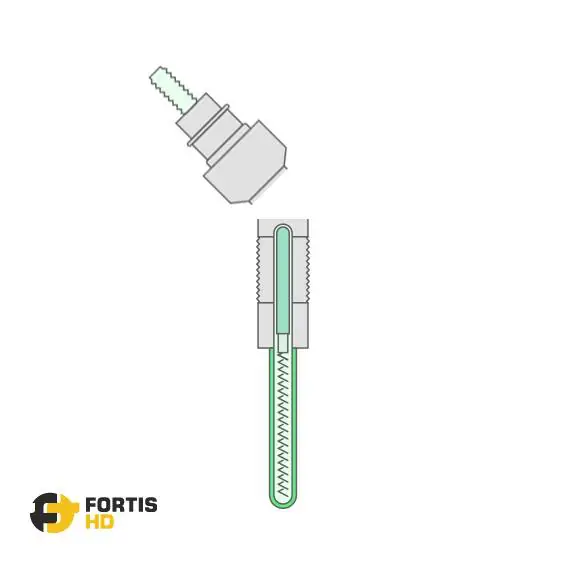

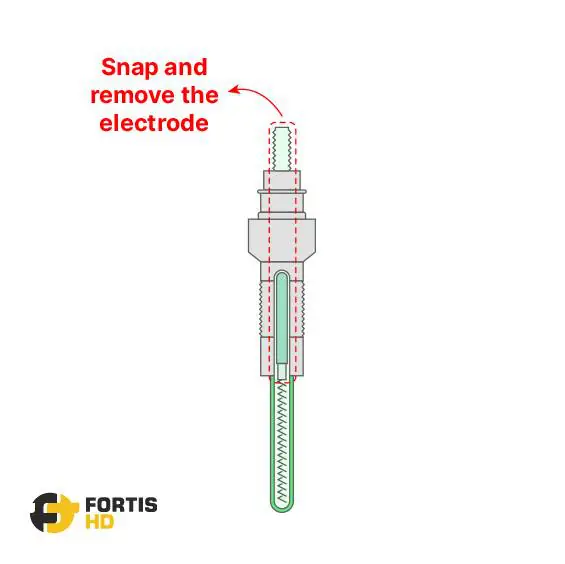

Before starting to drill, you need to get rid of the electrode, which is the inner and hardest part of the glow plug. Leaving the electrode will deflect the drill, damaging the engine cylinder head.

Use one of the twist-off extractors–depending on your glow plug model–to snap off the electrode. Manufacturers leave a weak point at the bottom of the electrode. It‘ll snap there, letting us remove most of it.

Once the electrode is out, shred the glow plug thread using the left-hand drill bit. Here are some features that make our model so effective:

- The left-hand drill bites counterclockwise. It won’t drive the glow plug further into the cylinder but could loosen or drive it out.

- The drill bit’s self-centered technology avoids deviating and damaging the cylinder head.

- The TIN (titanium nitride) coating increases the bit’s hardness and keeps it sharp for longer. TIN also reduces friction, which leads to less heat generation.

After drilling, use a blower or a magnet to pick up the chips.

Now, use the M7 left-hand tap to thread the inner side of the glow plug remaining shell. Again, use a blower or a magnet to remove the chips.

Screw the M7x120 mm left-hand extractor to the glow plug. Snap the slide hammer adapter and your slide hammer to remove the broken glow plug.

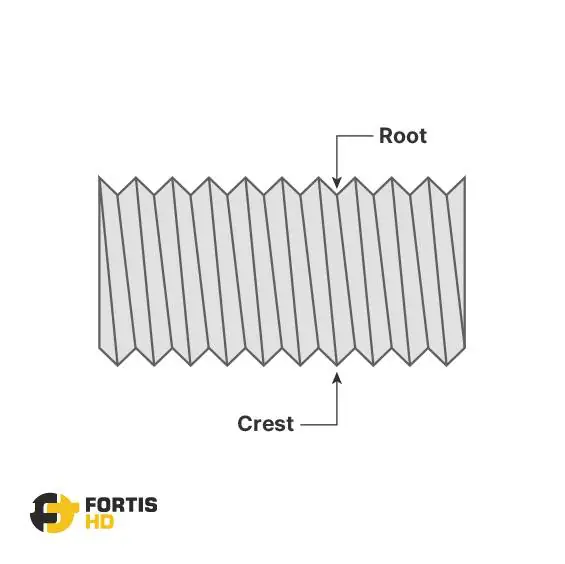

Finally, we need to clean the thread of the engine cylinder head because there will still be crest residues of the old glow plug shell inside the roots of the cylinder head. To do this, use the M10x1 tap and finish by cleaning the hole of chips and debris.

The M10x1 kit is designed for the professional mechanic to effectively and safely remove broken glow plugs. Visit the Fortis tool section to purchase yours.

The Glow Plug Came Out Without Part of Its Tip

In this case, the glow plug bit got stuck at the seat of the cylinder head.

Our Glow Plug Tip Removal Kit is your go-to tool.

The kit can remove stuck, broken tips of M10x1, M10x1.25, M9x1, and M8x1 glow plugs. It comes with the following tools:

- 3 sets of a drill bit, tap, and slide hammer adapter long enough to reach the cylinder head seat.

- 4 guides to insert the drill bit, the tap, and the adapter at the right angle.

- A slide hammer.

Start by assembling the drill bit with the corresponding guide–according to your glow plug size. Screw the guide into the cylinder head and carefully drive the bit until you reach the tip.

The bit has an oversized section to stop the bit at a suitable depth. Like the Broken Glow Plug Removal Tool, the drill bits have a TIN coating, which keeps them sharp for longer, reduces their heat generation, and increases their hardness.

Clean the hole of chips with a blower or a magnet.

Repeat the process with the tap and finally with the screwable slide hammer adapter to remove the stuck bit.

The Mueller Kueps glow plug tip removal kit lets you quickly remove broken tips without disassembling the engine cylinder head.

Conclusion

In general, removing seized glow plugs can lead to them breaking at the tip or above their threads. No matter how they break, you’ll safely and easily remove them with our tool kits.

Both scenarios involve the same steps—drilling, tapping, and extraction—with one difference: if the glow plug breaks at the top, you must remove the electrode first. It’s the toughest part of the glow plug and will deflect the drill bit, damaging the engine cylinder head.

However, if, for whatever reason, you need to drill high-grade steel, we have the best drill bits to tackle tough materials at Fortis. We delve deep into them in our article, “Easily Drill Extremely Hard Materials With Our Carbide Tip Drill Kit.”

Check out the tool section on our website and spread the word with friends and colleagues who still struggle with stuck glow plugs.