Good heavy equipment operator practices include properly parking the machine at the end of the work shift, especially with long-range components like the John Deere 135G Excavator.

Carelessly parking an excavator will cause premature wear on its hydraulic components, risks of breakdowns, and, even worse, deadly accidents.

Want to see the video version?

Common Mistake

Some operators turn their machines off and leave the components (bucket, stick, boom) suspended.

Why Is It a Mistake?

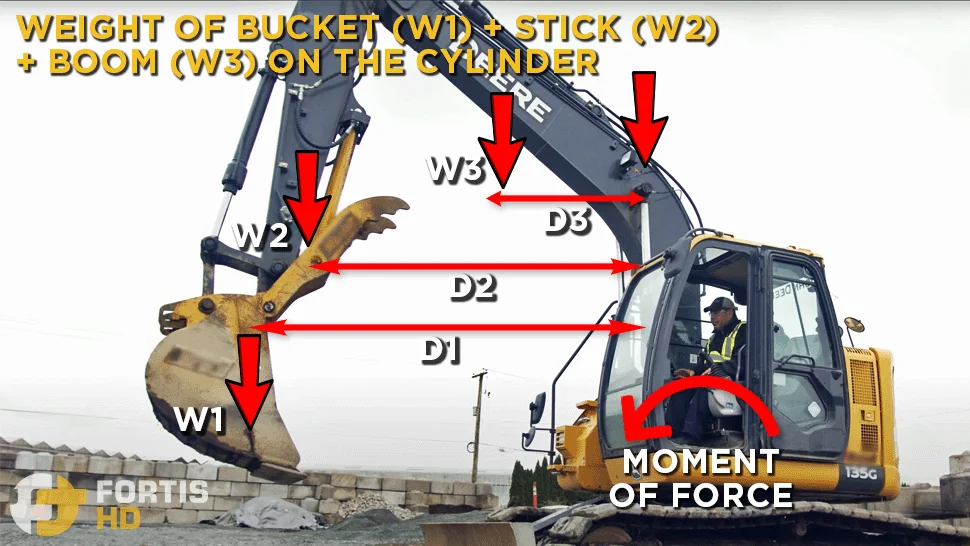

When you leave the machine components suspended, the boom’s cylinders hold the weight of the boom, stick, and bucket. Also, there’s a moment of force acting on the cylinders (the weight of the suspended components multiplied by their distances to the axis of rotation — the boom base pin).

The forces, acting for an extended amount of time, cause premature wear on the seals of cylinders, pistons, and valves.

In old machines, suspended hydraulics might fail and suddenly crash down.

Whether you parked the machine with the components suspended or got stuck in that way, don’t ever walk underneath the bucket, stick, or boom.

Correct Way To Park an Excavator

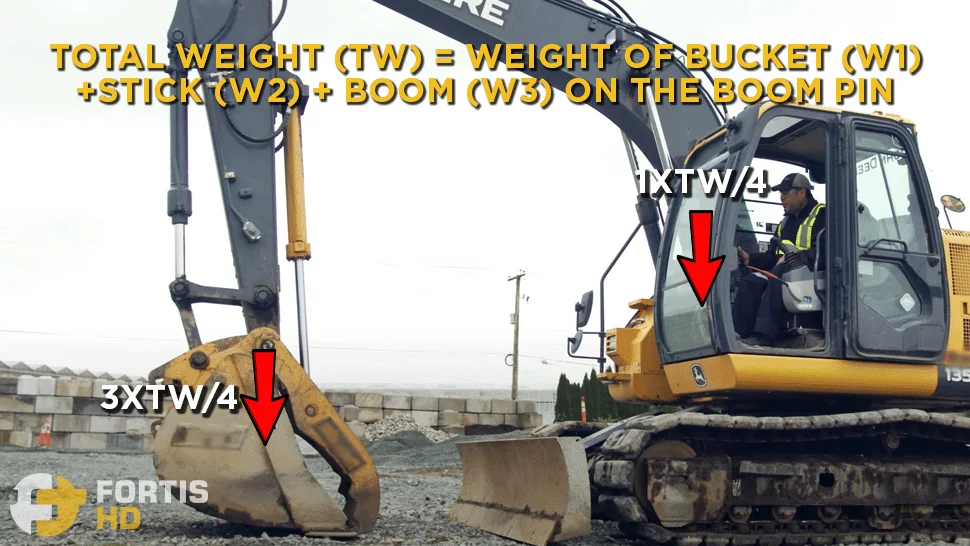

Put the bucket on the ground and bring the thumb all the way down. Most weight from the components will be transferred from the stick and bucket to the ground. Notice that the moment of force is gone as well.

Don’t forget the blade. Bring it down on the floor, too.

Finally, discharge the stored hydraulic energy of the pilot circuit. Otherwise, there’s a risk of accidental movement of the excavator’s components.

Some excavators have a feature allowing you to gradually use the operator controls to release the accumulator’s pressure. Turn the ignition key to the “on” position and move the levers around for about a minute.

![]()

For more tips on properly maintaining, servicing, and operating your machinery, visit the Fortis HD blog section. We also have a wide stock of high-quality aftermarket undercarriage parts to keep your heavy equipment in peak condition.