Skid steers are versatile machines utilized widely worldwide in various industries, from construction to landscaping.

One of the vital components that influence the performance of these machines is their tracks. In essence, selecting the right skid steer tracks can significantly improve your skid steer’s efficiency and operation, whether working in muddy conditions or snow-covered terrains.

However, with the market filled with many options, identifying the best skid steer tracks becomes a daunting task for many.

This article aims to ease that process by guiding you toward the best choices available, focusing on Bobcat, a brand synonymous with durability and performance in the industry.

Table of Content

The Importance of Rubber Tracks on Skid Steer Loaders

Unlike traditional steel tracks, rubber tracks offer many benefits that significantly enhance the operation of your skid steer machine, irrespective of the working environment.

Firstly, rubber tracks provide superior traction. When dealing with challenging surfaces like mud, snow, or uneven terrain, rubber tracks offer the necessary grip to prevent the skid steer from slipping or de-tracking.

As a result, they ensure a smooth and stable operation, reducing the risks associated with operating heavy machinery.

Secondly, rubber tracks cause less damage to the ground surface than their steel counterparts. This feature makes them great for tasks requiring minimal environmental disturbance, like landscaping or delicate construction projects.

A drawback to consider, however, is that rubber tracks can wear out faster than steel tracks in highly abrasive environments or when misused.

Moreover, they can be more expensive initially, but the potential for higher productivity and lower ground damage can offset this cost over time.

When you consider the durability, smooth ride, and superior traction rubber tracks offer, it’s clear why they are a significant consideration when hunting for the best skid steer tracks.

Compact Track Loaders vs. Skid Steers: Which is Better?

Regarding the discussion of compact track loaders (CTLs), and skid steers, both machines have distinct advantages, each with pros and cons.

Skid steers, equipped with either tires or rubber tracks, are prized for their maneuverability, compact size, and versatility. They work great in tight spaces, allowing you to turn 360 degrees in place.

This versatility makes skid steers an excellent option for various job site tasks, ranging from material handling to excavation. However, their performance can suffer in muddy or unstable conditions.

On the other hand, compact track loaders, which use rubber tracks, are known for their low ground pressure, superior traction, and stability.

The low ground pressure helps CTLs to float on soft or wet terrains, thereby minimizing soil compaction. Moreover, due to their wider tracks, CTLs provide superior traction and stability, especially in challenging terrains like mud or snow, making them well-suited for heavy-duty applications.

Comparatively, CTLs are often more expensive than skid steers and may require more maintenance due to the complexity of the undercarriage.

Ultimately, the choice between a skid steer and a compact track loader depends on the type of work, terrain, equipment, and specific demands of your project.

Whether you opt for a skid steer or a CTL, choosing the right rubber tracks remains essential to ensure optimum performance.

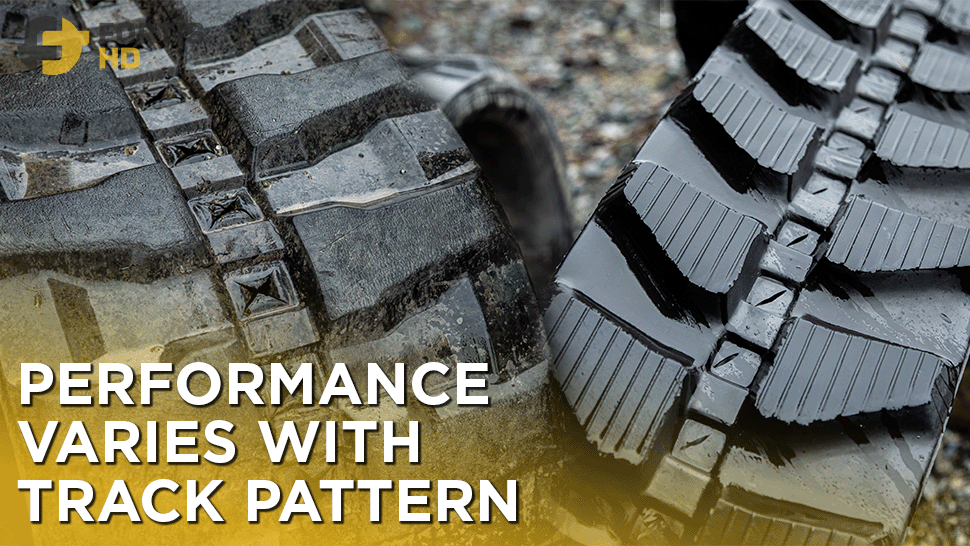

A Closer Look at Different Types of Skid Steer Tracks

Understanding the nuances of different track patterns is crucial to choose bobcat tracks for your needs. Each track pattern provides unique advantages, making them more suited for certain tasks or terrains.

C Pattern tracks, called Continuous C pattern tracks, are characterized by a straight bar design running continuously around the track. This design provides excellent traction, making it a good choice for muddy or icy conditions. It is ideal for rough terrains and heavy-duty applications because it reduces mud packing.

With their zig-zagging tread pattern, Zig Zag pattern tracks are known for their smooth operation and superior traction on hard surfaces. They are great for light-duty tasks on concrete or pavement where traction is paramount. This pattern also provides a smooth ride, making it a preferred option for operators. There might be better choices for soft and muddy terrains.

Multi-Bar Lug patterns are another prevalent design. They provide superior traction while ensuring low ground pressure, reducing the impact on soft terrains. The pattern is perfect for landscaping due to its durable, turf-friendly design.

Choosing between these different tracks also depends on the nature of the tasks. To make an informed decision, check out this extensive collection of Bobcat Skid Steer Tracks at Fortis HD.

Multi-bar lug pattern

C-pattern

Zigzag pattern

Hex pattern

H-pattern

Block pattern

Recommended Tracks for Specific Bobcat Models

Understanding the unique requirements of your Bobcat skid steer model is key to optimizing its performance. Here, we provide specific recommendations for a selection of popular models:

- Bobcat T190: Known for its compact size and lift-and-tilt solid breakout forces, the T190 works well with C Pattern tracks. The straight bar design of these tracks, coupled with the T190’s power, enhances traction, making it ideal for rough terrains.

- Bobcat T300: This is a larger model designed for heavy-duty applications. Zig Zag pattern tracks can be a good fit due to their robust design and superior traction on hard surfaces. Their smooth ride quality also reduces wear on the machine, prolonging its service life.

- Bobcat T650: With its vertical lift path and improved pushing power, the T650 benefits from Multi-Bar Lug patterns. They offer excellent traction while maintaining low ground pressure, reducing strain on the T650’s drive mechanism and ensuring smooth operation on soft terrains.

- Bobcat T770: As one of the most powerful models, the T770 requires a robust track to handle its power. The C Pattern or Multi-Bar Lug pattern would be suitable, offering excellent traction for heavy-duty tasks.

- Bobcat 331: This mini excavator model can benefit from Zig Zag pattern tracks, which provide a smooth ride and excellent traction on hard surfaces. Their efficient performance can help boost the 331’s productivity during light-duty tasks.

Correct track size is essential to ensure optimal performance and easy installation. At Fortis HD, we provide OEM-certified rubber tracks, guaranteeing quality and compatibility with your Bobcat skid steer models. Always consider the nature of your tasks, the type of terrain you’ll be working on, and the specific requirements of your Bobcat model to make the best choice.

Quantifiable Performance of Different Skid Steer Tracks

The performance of different skid steer tracks can be measured in various ways. Let’s delve into the specifics:

- Traction: The C Pattern track, with its continuous straight bar design, typically provides around 30% more traction in muddy or icy conditions compared to traditional Zig Zag patterns. This increased traction can significantly improve the efficiency of your skid steer operations in challenging terrains.

- Durability: Regarding longevity, Multi-Bar Lug pattern tracks can last up to 50% longer under similar working conditions than other track patterns. This durability can help reduce the frequency and costs of track replacements, contributing to the overall productivity of your skid steer operations.

- Ground Pressure: The Zig Zag and Multi-Bar Lug pattern tracks are designed to distribute the machine’s weight more evenly, leading to a 20% reduction in ground pressure compared to other track patterns. This reduced pressure can be crucial in minimizing damage to soft terrains.

- Productivity: While exact figures can depend on the specific task and conditions, choosing the correct track pattern for your skid steer could increase productivity by up to 25%. For instance, a C Pattern track could enhance performance in heavy-duty tasks, while a Zig Zag pattern might be ideal for light-duty tasks on hard surfaces.

We understand the importance of these factors and provide OEM certified rubber tracks. These tracks meet high-quality standards and are designed to fit your Bobcat skid steer models perfectly. It’s important to remember that while these figures can provide a general idea, actual performance may vary based on various factors, including your specific project requirements and operating conditions.

Real-World Application Scenarios

Here are a few examples that showcase how our Fortis HD OEM certified rubber tracks have proven effective in actual work scenarios:

- Bobcat T190 with C Pattern Tracks: In a construction site mired with thick mud, a Bobcat T190 equipped with our C Pattern tracks demonstrated exceptional performance. The continuous bar design allowed the skid steer to maintain excellent traction, reducing time spent stuck in the mud and increasing the efficiency of the operation.

- Bobcat T300 with Zig Zag Tracks: On a commercial project with significant work on concrete surfaces, a Bobcat T300 fitted with our Zig Zag pattern tracks showed superior handling. The tracks allowed for a smooth ride while maintaining excellent traction on the hard surface, making it ideal for such projects.

- Bobcat T650 with Multi-Bar Lug Tracks: In a landscaping task on soft terrain, a Bobcat T650 using our Multi-Bar Lug pattern tracks worked efficiently while minimizing ground disturbance. The lower ground pressure provided by this track design ensures a turf-friendly operation.

These scenarios illustrate the importance of selecting the right track design based on your tasks and work environment.

Choosing the Best Skid Steer Tracks for Specific Tasks

With the understanding of different track tread patterns, let’s explore how to choose skid steer tracks for specific tasks. For snow removal, consider tracks with high traction, such as tread patterns like the C Pattern or Zig Zag pattern tracks. These tracks provide the required grip to handle icy conditions.

A track tread pattern like the C Pattern or Multi-Bar Lug, which offers excellent traction while maintaining low ground pressure, is a wise choice when dealing with muddy or soft terrains. These tracks help the skid steer float on the soft surface without sinking, thus ensuring smooth operation.

Lastly, a track pattern like the Multi-Bar Lug is an excellent choice for tasks requiring minimal ground disturbance, like landscaping or golf course maintenance. Its turf-friendly design ensures minimal damage to soft surfaces.

In the debate between Bobcat tires and tracks, both have their merits. However, tracks, particularly rubber tracks, offer better traction and stability, especially in challenging terrains. They also cause less damage to the ground, making them a more suitable choice for various applications.

Final thoughts

After a comprehensive analysis, it’s clear that the best Bobcat tracks depend on the specific demands of your task and terrain.

For tasks requiring strong traction on soft or icy terrains, the C Pattern is a good fit. The Zig Zag pattern would serve you well for tasks on hard surfaces. And for turf-friendly applications, the Multi-Bar Lug is the way to go.

So, invest in Bobcat Skid Steer Tracks that match your operational needs. Carefully consider the task, terrain, and specific project requirements. Maximize your skid steer operations’ efficiency, productivity, and safety.

FAQs

How does tread pattern affect skid steer performance?

The tread pattern on skid steer tracks directly impacts the machine’s traction and stability, making it one of the most important factors in determining a skid steer’s performance. For example, C pattern tracks offer excellent traction, making them suitable for rough terrains or heavy-duty applications. On the other hand, Zig Zag pattern tracks ensure a smooth ride and superior traction on hard surfaces, making them suitable for tasks on concrete or pavement. Therefore, understanding your job requirements and the terrain, you’ll be operating on will help you select the most suitable tread pattern.

What should I consider when buying replacement tracks for my Bobcat skid steer?

When buying replacement tracks for your Bobcat skid steer, consider the following factors: the type of terrain, the tasks you’ll be performing, and the desired longevity of the bobcat rubber tracks. Other considerations include track width and rubber compound, which affect the machine’s weight distribution and durability. You should also ensure that the replacement tracks meet the OEM specifications for a proper fit and optimum performance. Lastly, consider buying from trusted suppliers, like Fortis HD, for quality assurance.

How do rubber track sizes impact the performance and application of the skid steer?

The size of the rubber tracks plays a significant role in determining the machine’s ground pressure, traction, and stability. Larger tracks distribute the machine’s weight over a larger surface area, reducing the ground pressure and improving the machine’s floatation on soft surfaces. Conversely, smaller, narrow tracks may offer better maneuverability in tight spaces but may increase the ground pressure. Thus, understanding the specific requirements of your job and the limitations of your job site can help determine the most suitable rubber track and size for your skid steer.