Greasing excavator fittings helps the machine move all working parts smoothly. You want to make sure the fittings have enough grease so there won’t be friction between moving components that cause malfunctions or failures. These steps can be used on any make and model of heavy equipment, including excavators and skid steers.

Table of Content

Step 1: Select the Grease Gun

There are several different grease guns that may be used. You can use an air grease gun, electric grease gun, or mechanical grease gun with a lever. If using a mechanical grease gun, it isn’t advisable to use the lever one with a pistol grip because it can make your hands sore when greasing a lot of fittings.

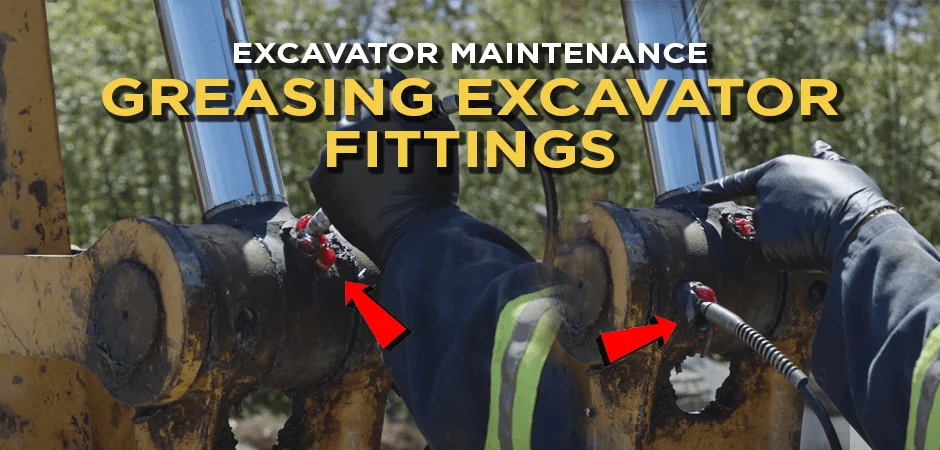

Step 2: Grease Moving Points

Any moving point on the machine has a grease nipple, including the arm and the bucket. Before greasing the fittings, always wipe them off to prevent contaminants from getting inside. Fit the end of the grease point on the nipple and apply grease.

Step 3: Fill Cavities

There are times when grease doesn’t immediately come out. This may be an indication that there is a cavity inside that requires more grease than expected. Continue to push grease inside until the cavity is filled as you will see grease come out.

Step 4: Grease Multiple Nipples on Pins

For excavators that have buckets and booms, they will have multiple pins, which make up the movable part areas. Each area may have several nipples that will take grease. Grease every nipple along the pin area even when they are near each other. Every thumb and cylinder will also have grease nipples. Sometimes they may be hard to find. The nipple may be located farther up the machine as the nipple will have a hose inside that will lead to the thumb or cylinder.

Step 5: Grease Top of Stick Cylinders

You do not have to climb on top of the boom or use a ladder to grease the boom’s hydraulic cylinders or stick cylinders. There will be a centralized location lower down for the grease nipples. These fittings will push grease to both bushings on the boom base, the top of the hydraulic cylinders for the boom, and the stick cylinder that mounts to the boom.