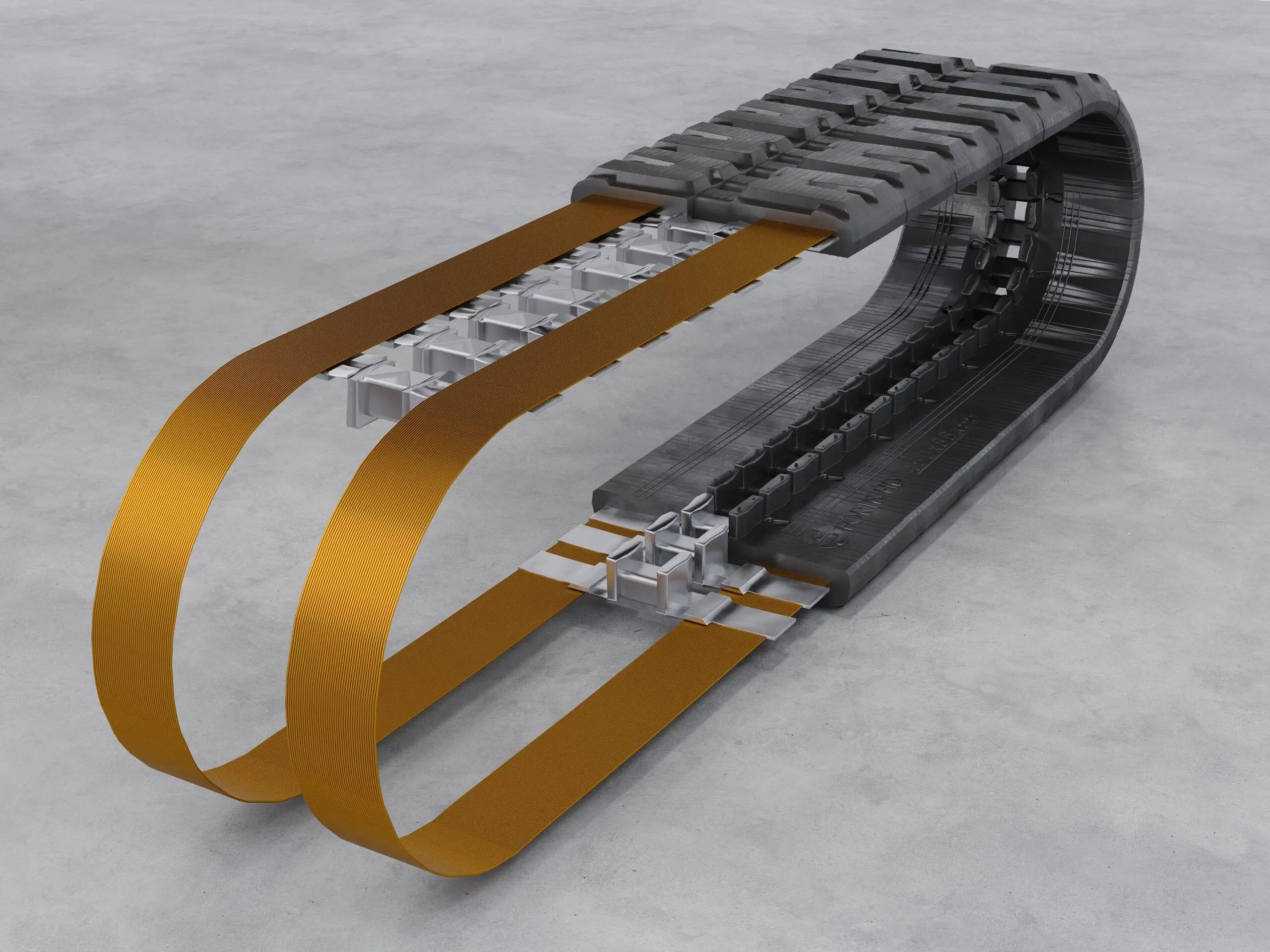

Superior Cable System

With a higher strand count and uniform

placement, our tracks offer greater strength

than the competition.

Get Peace of Mind With Our Industry-leading 2-year Warranty on All Rubber Track Purchases!

SKU: SKU:P026595

We collaborate with Tekamo HD's network of 500+ mechanics across the US and Canada. Once you order the tracks, our parts team will find a qualified mechanic to install them for you. If you can’t install these rubber tracks yourself or don’t have access to a local mechanic, our network is here to assist you.

Status : In Stock

Price per track

Couldn't load pickup availability

With a higher strand count and uniform

placement, our tracks offer greater strength

than the competition.

Looking for a heavy duty track for your John Deere 325? Fortis HD has you covered.

H Pattern or C Lug tread – The H or C track patterns are the most commonly used treads for tracks. They can easily maneuver over mud, snow, dirt, rocks or clay.

If traction is important to you, then zig zag patterned rubber tracks is the way to go. Zig zag treads are excellent for snow, mud and clay surfaces. These types of tracks will also reduce vibration of your machine, which will help with slippery surfaces.

The straight bar tread is specifically meant for wet and muddy surfaces. If you operate at high speeds, these tracks give you great traction and maneuverability.

If you’re dealing with gravel or a loose terrain, a multi bar tread might be your best option. However, these tracks will also work well on a hard surface and snow without issues. Think of them as your “all-season tracks”.

Designed with geometric blocks, this tread pattern offers a balanced blend of grip and durability. Suited for both hard surfaces and loose terrain, the Block Pattern minimizes vibration for a smoother ride. Whether operating on concrete or mud, experience consistent, efficient performance.

Each track is represented by a measurement broken into three parts: Track Width (mm), Pitch Distance (mm), and Number of Links — example: 320x86x54.

Use a tape measure to find the track width and pitch distance. The best way to count the number of links is to put a piece of tape on the link you’re counting, or just clean the first link and count up until you get back to it. Just make sure not to count the first one twice.

General rule is that rubber tracks last between 1,200 and 1,600 operating hours. However, this depends a lot on the conditions of the ground that your heavy equipment operates on. If your heavy equipment is put to use on sharp or rocky terrain, you are more likely to rip your rubber tracks and decrease the amount of hours that they will last.

Rips in the rubber, significantly decreased tread depth, or loose tracks (meaning poor track tension) are all indicators that it’s time to replace your rubber tracks. Loose tracks could also mean that you are low on track grease, so make sure you check your track grease (via the track adjuster grease valve) before assuming you need to replace rubber tracks on your excavator or skid steer.

Look up rubber recycling facilities in your area and ask them if you can dispose of your old rubber tracks. Otherwise, get creative! Some people will use their old rubber tracks as planter rings in their gardens, or for other landscaping purposes.

Installing rubber tracks is not as hard as you think! Check out our tutorial videos:

Our guarantee protects selected parts against damages in the form of premature

wear, mis-fitment, and manufacturer defects.

Get a full refund if you decide to cancel your order before your replacement

parts have left our warehouse.

How to install new tracks?

How to measure your tracks?