If you’ve been following our 1000 Hour Service series on the Komatsu PC200LC, welcome back!

In part 1 of our Komatsu Excavator 1000-Hour Service, we covered draining the engine oil and replacing the filters. As any heavy-duty mechanic knows, excavator engine oil change and filters is an important part of a preventative maintenance service. It keeps temperatures low and contaminants away from key components in your machine.

We’ll continue our 1000 Hour Service by delving into how to close the drains, refill the excavator engine oil, and check coolant levels.

Prefer to see a video tutorial instead?

Table of Content

Closing The Engine Oil Drain

After changing the engine oil filter you need to close the engine oil drain.

Pull the tube off and wait until the engine oil is filled back. Check the machine for any leaks before putting back all the panels.

Closing The Swing Gearbox Case Drain

Put the plug back in for the swing gearbox case and tighten it up. Don’t over-tighten, but it should definitely be nice and snug.

Changing Secondary Fuel Filter

Head back up on top of the Komatsu excavator. You can access the secondary fuel filter from here.

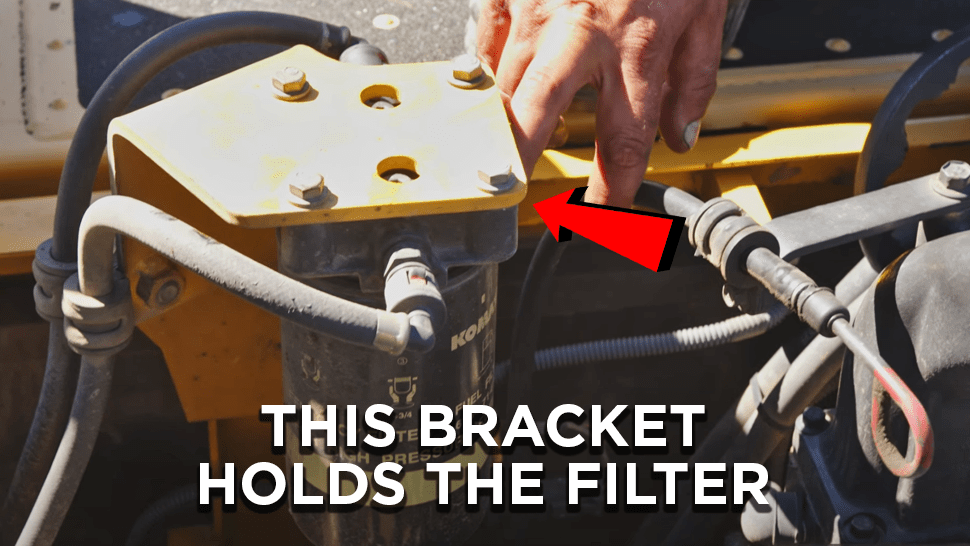

A bracket holds the filter head, which has the filter on it.

Loosen the filter with a filter spanner. It’s a good idea to put a rag underneath the filter while you do this to catch any dribbles. Careful not to drop the filter when it’s finally free to avoid excessive spillage.

Grab your new filter and lubricate the fuel filter O-ring with fuel. You should always replace that O-ring when you’re replacing the fuel filter. Replacement filters usually come with a new O-ring so it should be easy. Check the seal is in place when placing the filter back.

Hand-tighten the filter until it’s firmly in place. Never use a tool to tighten a spin-on filter.

Engine Oil Change

In part 1 we already drained the excavator engine oil. Now we need to fill it up again to finish off the excavator engine oil change.

Refer to the machine’s manual to find out what the excavator engine oil capacity is. You’ll need to fill it up to its maximum capacity.

When pouring in the oil, we recommend using a funnel with a screen. This prevents small particles from getting into the engine. You should also monitor the oil level while you pour to prevent overfilling.

When you’re done, use a clean dipstick to check the level of the engine oil.

Remember, the excavator engine oil doesn’t instantly drain to the bottom while you’re filling it. A lot of it stays in the top of the cylinder underneath the valve cover. On warm days it drains down relatively quickly, but in colder weather, it takes much longer. So give it a chance to settle all the way down before using the dipstick. Otherwise, your dipstick measurements won’t be accurate.

Now run the machine and recheck the excavator engine oil level with the dipstick. As we had already primed the filter, there shouldn’t be much oil loss. However, if you notice a significant difference between your measurements that could indicate there’s an issue.

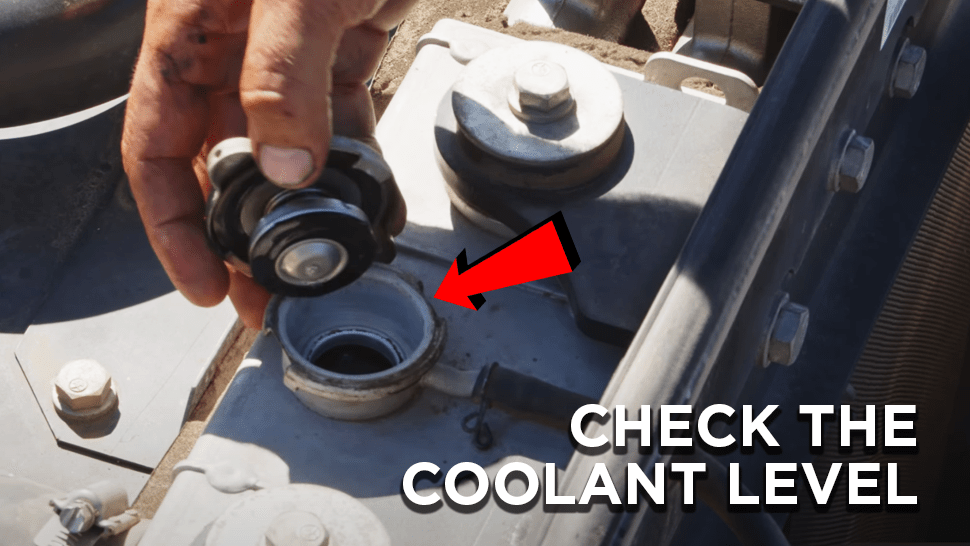

Checking Your Engine Coolant Levels

Twist off the cap on the coolant tank to visually inspect the level. Top up if necessary.

In addition to the coolant levels, you should also check what its freezing point is as well as the protection level. A lot of these machines will have a special coolant filter that helps protect the machine from electrolysis that happens inside the engine block.

If your machine doesn’t, you can get additives and coolants for diesel engines that have that stuff in it. There are also pH test strips available to check your coolant protection level and the DCA charge.

End Notes

That’s how you change the engine oil in a big excavator. In the Komatsu Excavator 1000-Hour Service part 3, we’ll be covering how to change the hydraulic filter and foam breather filter, as well as refilling the swing gearbox oil.