Featured Tools

+

+

The mid-size Cat 259D3 is a member of the D3 equipment series and one of the most popular compact track loaders among Americans. It competes for the #1 place in several states, mainly against the Kubota SVL75-2 and the Bobcat MT100.

Subtle changes to the cab, undercarriage, and new technological features have made the 259D3 more comfortable, durable, and efficient than the previous model.

Yet, there is still room for improvement. Let’s break down this popular compact track loader’s specs to see what shines and what doesn’t.

Photo source: www.youtube.com/@ZieglerCAT

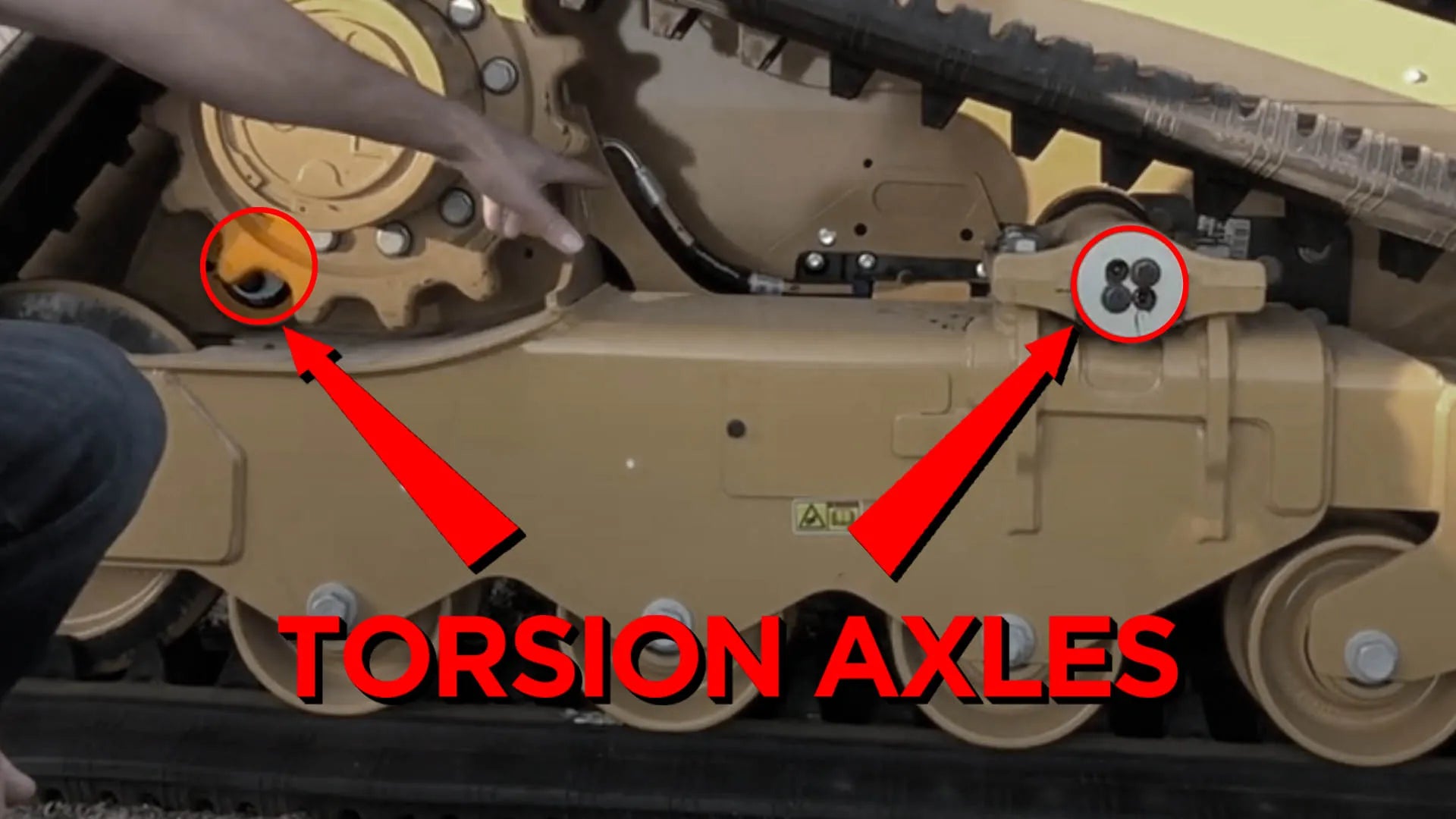

While most compact track loaders have rigid undercarriages, the 259D3 has torsion axles for independent side-by-side track suspension. They are similar to torsion arm trailer axles, where an inner steel bar rotates against four rubber cords.

The torsion axles make the undercarriage conform to the ground condition and isolate the operator and the machine chassis from vibrations. Besides a smoother ride—even at high travel speeds—the suspended undercarriage system improves material retention, traction, and flotation.

Since the axles dampen the vibrations, they help to extend the tracks’ useful life and prevent cracks in the frames.

With over 20 years of experience, Fortis HD is an OEM certified provider. Our Cat 259D3 tracks are designed as OEM replacements for most machines, ensuring a perfect fit and superior performance.

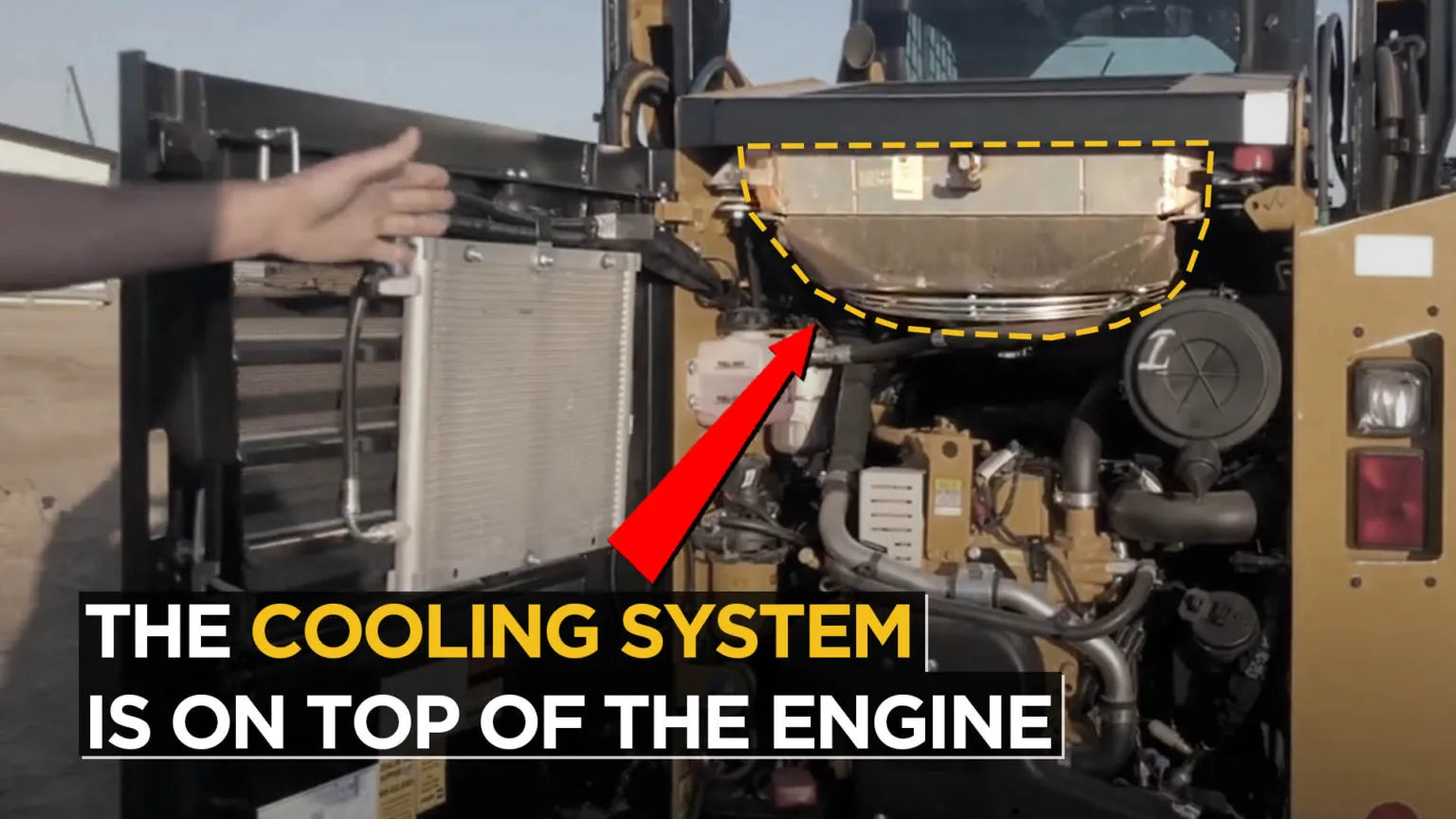

The final drive hoses on the 259D3 have a new routing. Instead of coming out from the belly through a rectangular opening, there’s a plastic bulkhead. It prevents dirt, mud, and debris from getting into the machine’s belly—a constant problem on the 259D.

Photo source: www.youtube.com/@ZieglerCAT

The bulkhead positions the hydraulic hoses in a way that offers better damage protection and makes digging out material from the undercarriage easier.

The triple-flanged rollers and idlers significantly reduce derailment. The front idler is also a few inches lower than the previous version for more ground contact and stability.

At Fortis HD, we have premium quality undercarriage parts designed for Cat track loaders.

They are available at a fraction of the cost that you would expect to pay at a Cat dealer and are built to deliver performance, reliability, and durability.

The one-piece sealed and pressurized cab and the undercarriage suspension greatly contribute to the operator’s comfort. It has a wider entrance than the previous D model, the door opens at 90 degrees, and the step in front of the cab has wider openings for less buildup. Although the cab isn’t 100% sealed, it is cleaner than others, like the Takeuchi TL8.

Photo source: www.cat.com

The 259D3 has a heated seat with awesome air suspension and adjustable lumbar support—you can tilt it forward or backward.

It also features one of the best-feeling joysticks with an ISO pattern. The space between the joysticks is greater than before, thus providing more legroom. In addition, you can adjust the position of the joysticks and arm bars independently.

The HVAC system works great, though the vents are a bit down low.

Something that caught our attention was the cell phone holder. It’s in the upper left corner (near the power plug) and has an elastic band to hold the phone. Although it works fine, it might stretch over time and no longer work properly.

A nice detail from Cat is the high-vis safety features, which help you recognize them quickly. The hydraulic arms lockout, emergency door releases, and the ceiling tab—to lower the arms in the case of a dead engine—are all red. The seat belt is high-vis orange, so you can clearly see from the outside if the operator has it on.

The rear window also has an emergency exit tag. Pull down the tag to release the seal and push the window out.

Photo source: www.cat.com

The cabin is loud. According to the specs, the noise level inside the cab is 83 dB(A), while the top safe decibel level for humans is 70 dB (A).

Even though the plastic bulkhead improved the undercarriage design, it also made a whining noise, which is louder when the machine is not revving all the way up. You can opt for a rubber bulkhead instead of plastic to make your Cat 259D3 cab quieter.

The radio, DPF, and some grease fittings are in awkward locations on the Cat 259D3.

Like the Kubota SVL75-2, the radio is behind the operator, in the cab’s left corner.

The DPF (diesel particulate filter) is at the back of the engine bay. You must remove the engine to access it.

Two grease fittings are especially hard to reach, one between the frame and the cab and another behind each lift arm.

Let’s end with some performance issues of the Cat 259D3.

First, the bucket doesn’t curl back that far. To get the material to the back of the bucket, you must go full reverse, stop, and curl the bucket to snap the material to the back.

Second, most of the time, you must be at full throttle for the machine to operate normally. It doesn’t work well when it’s idle.

Third, to use high-flow attachments without a wiring harness, you must manually install a plug—which is quite expensive, around $200—to activate the machine’s high-flow setting. In fact, Cat replacement parts are expensive overall.

Most users wonder why there isn’t a standard button inside the cab to switch between regular and high-flow.

In our experience, these issues arise when engineers don’t put themselves in the operators’ shoes. In the end, users need to come up with their own fixes. In the case of the Cat 259D3 high-flow plug, some people buy an aftermarket plug and wire it up to a switch in the cabs.

The Cat 259D3 has unique smart features to boost efficiency regardless of having similar specs and, in some cases, lower than some competitors.

Photo source: www.cat.com

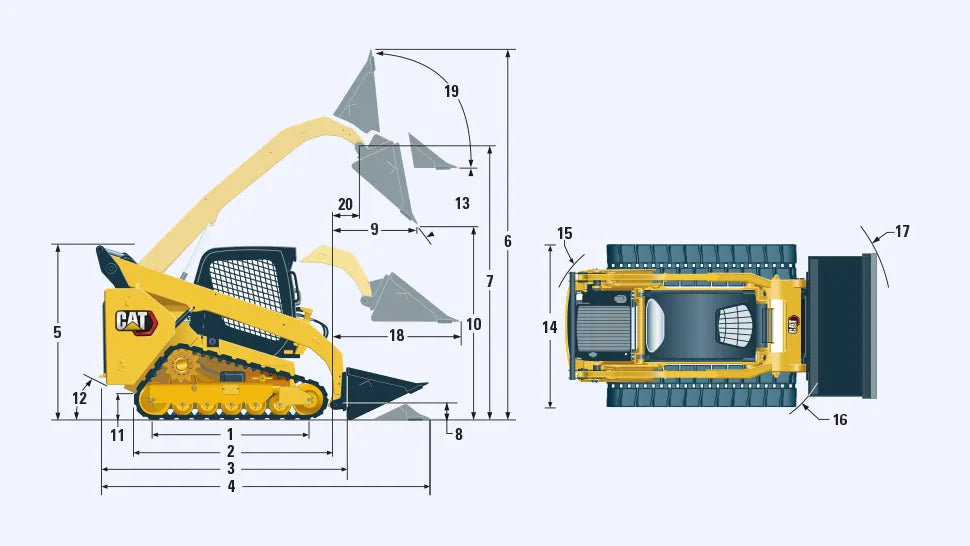

| Model in (mm) | Cat 259D3 | |

|---|---|---|

| 1 | Length of Track on Ground | 59 (1,499) |

| 2 | Overall Length of Track | 78.7 (1,999) |

| 3 | Length without Bucket | 108.9 (2,767) |

| 4 | Length with Bucket on Ground | 137.3 (3,486) |

| 5 | Height to Top of Cab | 83.1 (2,111) |

| 6 | Maximum Overall Height | 154.1 (3,915) |

| 7 | Bucket Pin Height at Maximum Lift | 121 (3,075) |

| 8 | Bucket Pin Height at Carry Position | 7.8 (198) |

| 9 | Reach at Maximum Lift and Dump | 23.9 (608) |

| 10 | Clearance at Maximum Lift and Dump | 89.9 (2,283) |

| 11 | Ground Clearance | 8.9 (226) |

| 12 | Departure Angle (degree) | 35 |

| 13 | Maximum Dump Angle (degree) | 52 |

| 14 | Vehicle Width with Narrow Tracks | 66 (1,676 ) |

| Vehicle Width with Wide Tracks | 69 (1,755) | |

| 15 | Turning Radius from Center – Machine Rear | 61.5 (1,561) |

| 16 | Turning Radius from Center – Coupler | 54.8 (1,392) |

| 17 | Turning Radius from Center – Bucket | 86 (2,184) |

| 18 | Maximum Reach with Arms Parallel to Ground | 51.4 (1,305) |

| 19 | Rack Back Angle at Maximum Height (degree) | 87 |

| 20 | Bucket Pin Reach at Maximum Lift | 9.4 (238) |

| Model in (mm) | Cat 259D3 | ||

|---|---|---|---|

| Engine | Model | Cat C3.3B | |

| Gross output - HP (kW) | 74.3 (55.4) | ||

| Loader Performance | |||

| ROC (-35% tipping load) - lbs (kg) | 2,010 (915) | ||

| Tipping load - lbs (kg) | 5,475 (2,610) | ||

| Breakout force, Tilt Cylinder - lbf (kg) | 4,965 (2,252) | ||

| Lift arm path | Vertical | ||

| Undercarriage | Track width | Narrow - in (mm) | 12.6 (320) |

| Wide - in (mm) | 15.4 (400) | ||

| Track rollers (per side) | 5 | ||

| Travel speed | Low - mph (km/h) | 5.9 (9.5) | |

| High - mph (km/h) | 8.5 (13.7) | ||

| Min. ground clearance - in (mm) | 8.9 (226) | ||

| Hydraulic System | Aux. hydraulic flow | Std. - gpm ( l/min) | 20 (76) |

| High. - gpm ( l/min) | 30 (112) | ||

| Aux. hydraulic pressure | psi (kgf/cm2) | 3,335 (234.53) | |

| Operating weight - lbs (kg) based on 165 lb (75 kg) operator | 8,987 (4,076) | ||

Caterpillar relies on smart and automation functions to increase the productivity and efficiency of the 259D3 track loader.

The most distinctive feature is the Smart Attachments.

When you connect a smart tool to the 259D3 (or any other Cat D3 equipment series), it recognizes the tool and changes the joystick controls to match the attachment functions.

Photo source: www.cat.com

As of 2024, three different Smart attachments are available:

Previous tech features like dual self-leveling, return to dig, and work tool positioner are still part of the Cat 259D3, but you can combine them for more efficiency this time.

While most brands have a self-leveling function only on the upward cycle, the Cat 259D3 allows a bucket or fork to maintain its level in both the upward and downward cycles.

The return to dig and work tool positioner features let you set your tool or attachment at a particular position and reset it once you finish a task. You can also automate repetitive functions when digging, loading, or operating an attachment with a specific desired angle.

So, for example, if you are trenching and need to take out the trencher to remove a stone or something blocking your path manually, the work tool positioner will reset the trencher at the exact working angle and level with the push of a button.

Other efficiency-oriented techs on the Cat 259D3 are Continuous Flow, Speed-Sensitive Ride Control, and Creep Control.

The continuous flow feature lets you run an attachment continuously without holding your thumb on the auxiliary. Think about it as the cruise control on your vehicle.

The Speed-Sensitive Ride Option activates to control the bucket linkage at a set speed. While the bucket moves up and down, it cushions your ride and reduces spillage.

The Creep Control, AKA snail mode, allows you to adjust the drive speed as the attachment runs full speed. So, no matter if you have the joystick all the way down, it holds the speed. It takes much less finesse for tasks like grading, bush hogging, or clearing land.

The table below shows some specs of five compact track loaders similar to the Cat 259D3:

| Hydraulic Flow (gpm) | Travel Speed (mph) | ||||||

|---|---|---|---|---|---|---|---|

| Model | Engine Gross Power (HP) | ROC 35% (lb) | Arm Breakout Force (lb) | Std. | High | Low | High |

| Cat 259D3 | 74.3 | 2,000 | 4,965 | 20 | 30 | 5.9 | 8.5 |

| Kubota SVL75-2 | 74.3 | 2,300 | 4,766 | 17.4 | 29.3 | 4.7 | 7.1 |

| Bobcat T66 | 74 | 2,450 | 4,474 | 23 | 30.5 | 7.2 | 10.2 |

| Gehl RT215 | 72 | 2,150 | 6,632 | 22 | 35.9 | 5.9 | 8.8 |

| New Holland C332 | 74 | 2,240 | 4,840 | 24.2 | 37.6 | 5.5 | 8.0 |

| Takeuchi TL8 | 74.3 | 2,105 | 6,709 | 18.4 | 33 | 4.7 | 7.0 |

The 259D3’s undercarriage suspension provides a smooth ride but also makes it tippy and keeps it at the lower lift end of the list—the rest of the CTLs have rigid undercarriages.

However, it provides superior traction since tracks conform better to the terrain, and the triple-flanged rollers on the Cat 259D3 compact track loader provide little to no derailment, unlike the Takeuchi TL8, which suffers from that issue, especially when working on slopes.

Like the SVL75-2 and Bobcat T66, the Cat 259D3 has a narrow back visibility due to its corner posts and crossbar. The New Holland C332 has the upper hand because of its super-boom design (no corner posts and a low crossbar), followed by the Takeuchi TL8 and the Gehl RT215.

The Cat 259D3, like the Bobcat T66, has electric over hydraulic controls. They are smoother, and you can fine-tune them to your preferences. On the other hand, the Gehl RT215 and Takeuchi TL8 have pilot over hydraulic controls, which are more responsive but a bit jerky.

Unlike the Takeuchi TL8 and the Kubota SVL75-2, the 259D3 has hydraulic couplers inside the lift arm, protecting against tearing damage. But Takeuchi and Kubota have roll-up doors, allowing you to open them even with the lift arms in the air.

While most CTLs have their oil sight glass separate from the cap fill, the 259D3 has its oil level gauge near the cap fill, making service and maintenance easier.

Finally, although Caterpillar equipment isn’t as DIY-oriented as Kubota, they have a great service department and will walk you through any problem.

Ironically, Cat’s efforts to provide operators with a soft ride with the suspension undercarriage have also led to complaints because grading is more difficult than compact track loaders with a rigid undercarriage.

The grading complaint pops up on several websites, such as AgTalk and Heavy Equipment Forum.

However, as a user on the LawnSite forum (who goes by the nickname bobcat_ron) states, the grading problem isn’t exclusively due to the undercarriage but a lack of operator skill, which led us to the testimonial of Dusty Rhodes, a landscape contractor and owner of Dirt Poor.

Dusty and his son have gotten the hang of grading with the Cat 259D3 compact track loader, and they prove it by showing you how they built a baseball field in the following video.

You can also let the smart grade attachment do the hard work so you can enjoy the comfort of the 259D3 cab, which is exactly what Tom Campbell (owner of Final Trim Excavations) and his crew do.

The combination of a suspension undercarriage, comfy cab, and smart technology features make the Caterpillar 259D3 an efficient and reliable compact track loader.

On the downside, the undercarriage torsion axles make grading challenging for most operators, and, like most CTLs, the cab is loud—above 70 dB(A).

Nevertheless, the 259D3 is one of the most popular machines across the US, not only due to its features but also thanks to a great service department.

Share this article with your tech-savvy friends so they can see how automation is reshaping the heavy equipment industry.