In this article, our heavy-duty mechanic will showcase his skills by repairing an old Massey Ferguson tractor.

A heavy-duty mechanic is not a farm mechanic but knows how to handle most heavy equipment. Let’s go through the step-by-step process to get this machine running.

This machine has a gasoline engine. The tractor is quite old, and these models were made in the mid-1960s. Let’s start with the initial inspection of this tractor.

Table of Content

Step 1: Initial Inspection

The first step is to inspect the tractor parts. It includes the transmission gearbox, PTO, final drive differential, and plow attachments.

Now open up the hood, and check the fuel and the coolant level. Put water in it to top it up. Also, fill up the gasoline tank.

You also need to connect a new battery. Pull up the spark plugs to understand the condition of the engine.

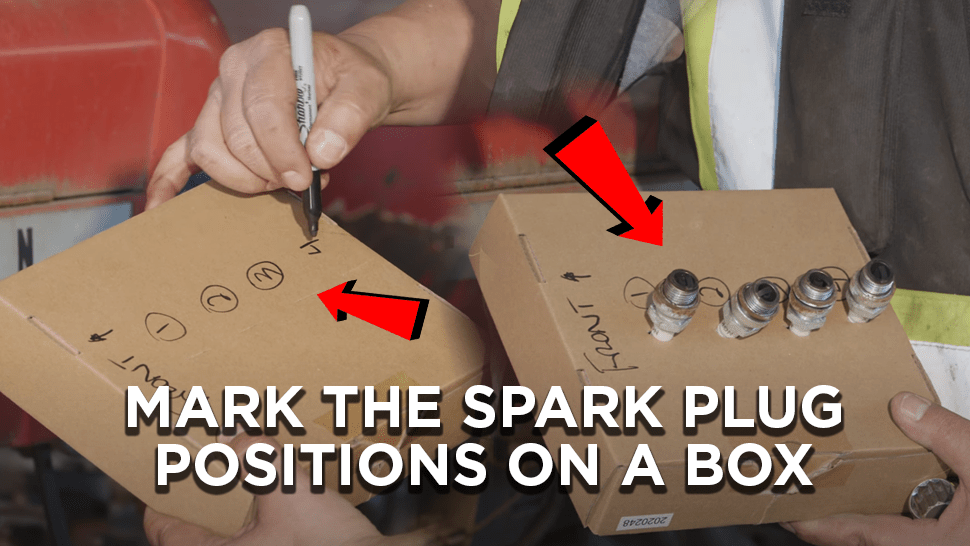

You can mark the spark plug numbers on a box to track the cylinder if one of the plugs is damaged. This technique is beneficial for keeping track of the cylinder.

Another critical factor to look for is the firing order, and In our case, it is 1,3,4, and 2. This order indicates that the rotor moves in a counterclockwise direction.

When you are inspecting the tractor parts, it’s a good idea to mark them up with tape. You don’t want to mix them up when reconnecting.

If you observe carbon on spark plugs, it could be because the fuel is not burning correctly. The carburetor may need some adjustments or overhauling. If all the spark plugs are the same, they are running balanced.

The golden brown or beige color indicates that the fuel is burning correctly. The black color indicates an issue in carburation or clogged air filters.

Inspect the condition of the distributor cap. Also, inspect the rotor and look for a spark. If there is no sign of a spark, everything is ok. This process is called carbon tracking.

The rotor not returning to its original position means the spring could be broken underneath. You can leave it as such for now. You already have the spark plugs out and can start turning over the engine by hand.

You can use the generator to turn over the engine manually. If the engine turns nicely, we can hook up the battery and check if it cranks over.

Step 2: Distributor Cap Inspection

Distributor cap inspection is a part of the tune-up process. It should have been done regularly during its life. Most heavy equipment is now electronic, and we don’t need such inspections until a specific mileage.

Check the rotor to see if it’s returning on its own. If not, there is a problem, and we must fix it. The electric spark comes from the ignition, goes to the center of the cap, and through the rotor, it matches up with the electrodes and finally goes out to the spark plug.

Step 3: Testing the Engine

You can leave the spark plugs out and check if the engine turns over. If there is no resistance on the engine, we can check if the starter works.

Since no key is available, we will bypass the starter to get cranking. We can provide a signal to the solenoid, which will activate the starter. This is how to bypass the key switch. If it turns over nicely, the next step is to do a compression check.

If we have significant compression, we are ready to start the tractor.

End Notes

Massey Ferguson tractor is an old machine. Our heav-duty mechanic has used his technical knowledge to get this machine started. These tips are essential to handle a tractor repair.

Let us know if you have any questions.