Refilling the engine oil helps the engine run smoothly. It allows you to drain old and dirty oil from the engine oil compartment and fill it up with cleaner engine oil that will work better with the machine. The steps in changing the engine oil can be used for any make or model of the excavator.

Table of Content

Step 1: Find Engine Fill

Open the hood. For a CAT 314E excavator, the engine fill is at the top of the valve cover. Some machines may have the engine fill along the side.

Step 2: Place in Oil

Remove the cap and put a funnel into the engine fill opening. Make sure to place the funnel in a way so that it doesn’t tip over or slide out when pouring in the oil. You may use mineral oil or synthetic oil depending on the excavator manufacturer’s specs. When pouring in the oil, some machines such as Hitachi may experience catastrophic failure due to the engine oil being poured in too quickly. The oil gets dumped into the intake system. To prevent this issue, take your time and pour in smaller amounts. Let the oil drain from the funnel and enter the compartment fully, then pour in more.

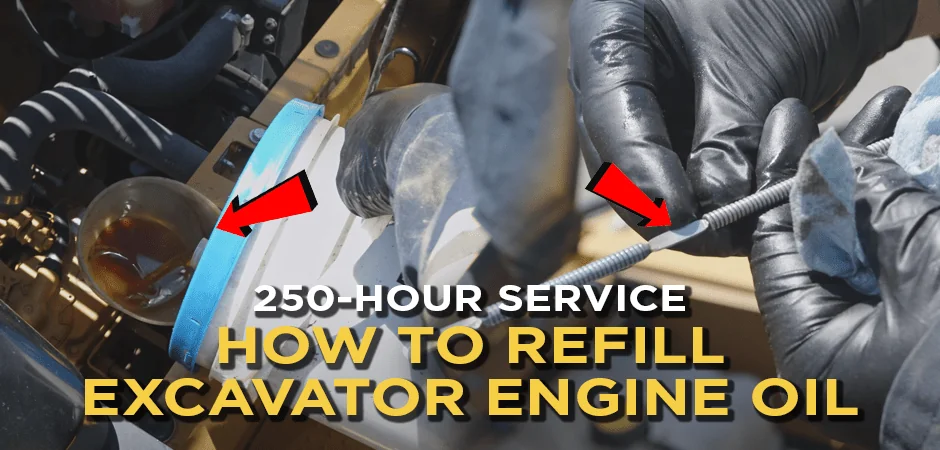

Step 3: Track Oil Level

Check the oil level by pulling out the oil dipstick located near the engine oil fill. Wipe the dipstick clean, place it back inside and then pull it out. You want the oil level to be between the L line and the H line on the dipstick. Add in more oil when needed.

Step 4: Start the Engine

Return the dipstick into the machine, remove the funnel and place on the cap. Start the machine as the engine oil filter will begin to fill up with oil. Let the machine run for 5 to 10 seconds. Sometimes a buzzer comes on, but that is okay. The buzzer is normal to indicate that there is low engine oil pressure. It will stay on until the engine oil filter is full.

Step 5: Top Off the Engine Fill

Turn off the machine and check the engine oil levels using the dipstick. Top off the oil fill compartment. Always clean the funnel before placing it into the hole as contaminants on the funnel will get inside. Once you reach the desired fill level, remove the funnel, and place the engine oil fill cap back on. Then close the lid.